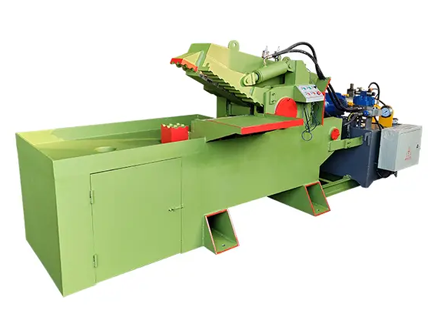

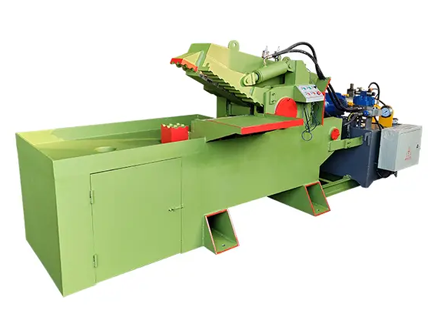

Scrap metal shears play a crucial role in the metal recycling and processing industry by efficiently cutting and resizing various types of metal scrap. These powerful machines help transform bulky, irregular scrap into manageable pieces for further processing, transport, or resale. However, the performance and longevity of scrap metal shears depend heavily on consistent and proper maintenance.

Regular maintenance is not just about keeping the equipment clean—it directly impacts cutting precision, operational efficiency, and overall machine lifespan. Neglecting routine care can lead to frequent breakdowns, unexpected downtime, costly repairs, and even safety hazards. On the other hand, a well-maintained scrap metal shear operates smoothly, consumes less energy, and maintains high productivity levels.

Daily Inspection Checklist

Regular daily inspections are the foundation of effective maintenance for scrap metal shears. By performing a quick yet thorough check before each operation, you can catch potential problems early, avoid unexpected downtime, and ensure safe and efficient machine performance. The key areas to focus on include hydraulic oil levels, blade condition, and hydraulic lines for leaks.

Hydraulic Oil Level

Hydraulic oil is the lifeblood of the scrap metal shear’s cutting system. Maintaining the correct oil level is essential for consistent hydraulic pressure and smooth machine operation. Before starting work each day, operators should:

Use the designated sight glass or dipstick to verify that the hydraulic oil is within the recommended range.

Top up the oil if levels fall below the minimum mark, using the type of hydraulic fluid specified by the manufacturer.

Check the oil for signs of contamination, such as discoloration or foaming, which can indicate internal leaks or air ingress requiring immediate attention.

Failing to maintain proper oil levels can result in reduced cutting force, overheating, and premature component wear.

Blade Condition

The scrap shear blades endure tremendous mechanical stress during cutting operations. Daily visual inspections help ensure the blades remain sharp, intact, and properly mounted. Key inspection points include:

Checking the cutting edges for chips, cracks, or uneven wear that could affect cutting quality.

Noticing any deformation or bending of blades, which may cause inefficient cuts or damage other components.

Verifying that blades are securely fastened without looseness or unusual vibration during operation.

Identifying blade issues early enables timely sharpening or replacement, preventing further damage and maintaining optimal performance.

Hydraulic Lines and Connections

Hydraulic hoses and fittings must be intact and leak-free to maintain system pressure and ensure operator safety. During daily inspections, look for:

Visible leaks, wet spots, or oil drips along hoses, connectors, and around seals.

Signs of wear, abrasion, cracking, or bulging on hose surfaces that could lead to sudden failure.

Properly tightened fittings and absence of corrosion or rust on connectors.

Promptly addressing any hydraulic leaks or damaged hoses helps avoid system malfunctions, environmental contamination, and safety risks.

Blade Sharpening and Replacement Cycles

The blades of a scrap metal shear are critical components that directly affect cutting performance, machine efficiency, and overall safety. Understanding when to sharpen or replace blades is essential to maintain smooth operation and avoid costly downtime.

How to Determine Blade Wear

Regularly assessing blade condition helps identify signs of wear or damage early. Operators and maintenance personnel should look for the following indicators:

Visual Damage: Inspect blades for chips, cracks, or deep nicks along the cutting edge. Such damage compromises cutting accuracy and can propagate, leading to blade failure.

Dulling of the Cutting Edge: Over time, blades lose their sharpness, resulting in rough or uneven cuts. This often manifests as increased cutting resistance, requiring more hydraulic force and slowing production.

Deformation or Bending: Warped or bent blades indicate mechanical stress or improper use, which can cause poor cut quality and may damage the shear’s frame or hydraulic system.

Increased Cycle Times or Energy Consumption: If the shear takes longer to complete cuts or uses more power than usual, blade dullness might be a contributing factor.

When to Sharpen Blades

Sharpening blades at the right intervals restores their cutting efficiency and extends their usable life. Consider these best practices:

Sharpen blades when cuts become visibly rough or when operators notice increased effort during cutting.

Follow manufacturer-recommended sharpening angles and procedures to avoid overheating or altering the blade’s geometry. Improper sharpening can weaken the blade and lead to premature failure.

Avoid over-sharpening, which shortens blade thickness and reduces strength. Each sharpening cycle should remove only the minimum material necessary.

Use professional grinding equipment or rely on specialized service providers for consistent and precise sharpening results.

When to Replace Blades

Despite regular sharpening, blades will eventually reach the end of their service life and require replacement. Replace blades when:

There are cracks, deep chips, or structural damage that cannot be safely repaired.

The blade thickness has been reduced beyond the manufacturer’s minimum safe limit due to repeated sharpening.

Cutting performance cannot be restored by sharpening, as indicated by persistent rough cuts or blade instability.

The blade’s mounting holes or surfaces are worn or damaged, causing poor alignment or vibration.

Timely blade replacement prevents damage to other shear components and maintains operational safety.

Hydraulic System Maintenance

The hydraulic system is the heart of a scrap metal shear, providing the powerful and controlled force necessary for efficient cutting. Proper maintenance of this system is vital to ensure reliable operation, extend equipment life, and avoid costly breakdowns. Key maintenance tasks include managing hydraulic oil quality, cleaning or replacing filters, and regularly inspecting hoses and connections.

Hydraulic Oil Replacement Cycle

Hydraulic oil lubricates, cools, and transmits power within the system. Over time, oil degrades due to heat, contamination, and oxidation, which can cause corrosion, wear, and reduced efficiency. To maintain optimal system performance:

Follow the manufacturer’s recommended hydraulic oil replacement intervals, typically ranging from 1,000 to 2,000 operating hours or annually, whichever comes first.

Regularly sample and test the oil for contamination, viscosity changes, or presence of water, which indicate the need for immediate replacement.

Use only high-quality, manufacturer-approved hydraulic fluids that meet specified viscosity and additive requirements to protect seals and components.

Always drain and refill the system properly, ensuring no air is trapped, which can cause cavitation and damage.

Filter Cleaning and Replacement

Filters play a crucial role in keeping hydraulic oil clean by removing dirt, metal particles, and other contaminants that accelerate component wear.

Inspect hydraulic filters daily or weekly depending on usage intensity and replace them according to the manufacturer’s guidelines.

Use genuine replacement filters designed specifically for your scrap shear model to ensure filtration efficiency and system compatibility.

If equipped, monitor filter indicators that alert when a filter is clogged or due for replacement.

Avoid running the system with a clogged filter, as it can restrict oil flow and cause system pressure drops or damage pumps.

Hose and Connection Inspection

Hydraulic hoses and fittings are under constant pressure and subject to wear from vibration, abrasion, and temperature changes.

Conduct routine visual inspections to check for cracks, leaks, bulging, or worn areas on hoses. Replace any damaged hoses immediately to prevent sudden failures.

Check all fittings and connections for tightness and signs of corrosion or damage. Loose fittings can cause leaks or pressure loss.

Use protective sleeves or clamps in areas prone to abrasion or contact with other machine parts.

Ensure that hoses are routed correctly without sharp bends or kinks that could reduce flow or increase wear.

Additional Tips for Hydraulic Maintenance

Monitor system temperature during operation and investigate any unusual increases, as overheating can degrade oil and damage seals.

Maintain proper system pressure settings according to manufacturer specifications to avoid overloading components.

Keep the hydraulic reservoir clean and sealed to prevent contamination and moisture ingress.

Lubrication and Moving Parts Care

Proper lubrication and regular care of moving parts are essential to ensure the smooth operation and longevity of scrap metal shears. Components such as guide rails, shafts, bearings, and hinges experience constant motion and friction, making them prone to wear and corrosion if not maintained properly. Effective lubrication reduces mechanical resistance, prevents overheating, and protects against rust and contamination.

Key Moving Parts to Lubricate

Guide Rails: These rails guide the moving parts of the shear, such as the cutting head or hydraulic cylinder components. Regular lubrication minimizes friction and prevents wear on the sliding surfaces.

Shafts and Pins: Shafts that connect mechanical parts and pins that act as pivot points need consistent lubrication to avoid seizing and excessive wear.

Bearings: Bearings support rotating or sliding motions and require appropriate grease to maintain low friction and prevent premature failure.

Hinges and Joints: Moving joints and hinges benefit from lubrication to maintain flexibility and prevent rust buildup.

Lubrication Best Practices

Use manufacturer-recommended lubricants, which typically include high-quality grease or oil formulated for heavy-duty industrial applications.

Apply lubricant at regular intervals as specified in the machine’s maintenance manual, with increased frequency in dusty or wet environments.

Clean moving parts before lubrication to remove old grease, dirt, or metal debris that can cause abrasion.

Avoid over-lubrication, which can attract dust and contaminants, potentially damaging the parts.

Rust Prevention and Protection

In addition to lubrication, apply rust inhibitors or corrosion-resistant coatings on exposed metal surfaces, especially if the equipment operates in humid or corrosive environments.

Inspect moving parts regularly for signs of rust or corrosion, and clean affected areas promptly to prevent spread.

Store the scrap metal shear in a dry, covered area when not in use to minimize moisture exposure.

Benefits of Proper Lubrication and Care

Reduced friction and wear extend component life and lower maintenance costs.

Smoother machine operation improves cutting precision and reduces energy consumption.

Prevention of rust and corrosion protects the equipment’s structural integrity and appearance.

Decreased risk of unexpected breakdowns, enhancing overall equipment reliability and uptime.

Software and Control System Check

Modern scrap metal shears increasingly rely on automated control systems to enhance precision, safety, and operational efficiency. Maintaining the software and control hardware is therefore an essential aspect of overall equipment upkeep.

PLC System Upgrades and Maintenance

Programmable Logic Controllers (PLCs) serve as the brain of automated shears, managing cutting sequences, safety interlocks, and diagnostics.

Regular Firmware Updates: Keep the PLC firmware and software updated with the latest versions provided by the manufacturer. Updates often include performance improvements, bug fixes, and enhanced security features.

Backup and Restore Procedures: Maintain current backups of PLC programs and configurations. This ensures rapid recovery in case of software corruption or hardware replacement.

Diagnostic Checks: Use built-in diagnostic tools to monitor system health, identify faults early, and schedule preventive repairs before failures occur.

Calibration: Periodically verify and calibrate sensors and control devices to maintain cutting accuracy and consistent performance.

Operator Panel Inspection

The human-machine interface (HMI), including touchscreens, buttons, and indicator lights, should be regularly checked for functionality.

Ensure all control buttons respond correctly and display panels show accurate information.

Clean the interface regularly to prevent dust and grime buildup that can impair responsiveness.

Test emergency stop functions and safety interlocks to guarantee immediate machine shutdown when required.

Replace worn or damaged components promptly to avoid operator errors or safety hazards.

Proper maintenance of the control system not only prolongs equipment life but also enhances operational reliability and workplace safety.

Conclusion

Consistent preventive maintenance is a cornerstone of maximizing the efficiency, reliability, and lifespan of scrap metal shears. By regularly inspecting hydraulic systems, sharpening blades, lubricating moving parts, and maintaining control software, operators can significantly reduce the risk of unexpected breakdowns, costly repairs, and downtime.

Choosing a reputable manufacturer like Jiangsu Huanhong Hydraulic Co., Ltd., which offers not only high-quality hydraulic scrap metal shears but also professional after-sales support, ensures that your equipment receives expert care throughout its service life. Huanhong’s commitment to innovation and customer service helps recycling operations maintain peak performance while minimizing total cost of ownership.

For more information on customized scrap metal shear solutions and maintenance support, visit www.huanhongbaler.com and contact their experienced technical team today.