Choosing the right horizontal baler can seem hard at first. Every facility deals with different materials and waste amounts. You need a baler that fits your space. It should match your daily waste output. It must also keep your team safe. Many waste management places have problems like picking the right size. They need to make sure the baler fits. They also have to plan for future growth. As you read, think about what you need now. Also, think about where you want your work to go next.

Key Takeaways

Pick a baler that matches your main waste type and daily amount. This will help your work stay simple and fast.

Check if your facility has enough room and a safe setup for the baler and your workers.

Find features like automatic tying, strong pressing, and easy care. These can help you save time and money.

Think about the future. Choose a baler that can handle more waste if your business grows.

Teach your team how to use the baler and keep it working well. This keeps everyone safe and helps things run smoothly.

Understanding Waste Output

Material Types

Start by asking what kind of waste you have most. Many places deal with paper, cardboard, plastics, metals, e-waste, tires, rubber, and textiles. You might see lots of cardboard boxes, plastic bottles, or metal cans. The packaging you use can change your waste. If you have big plastics or heavy metals, you need a strong baler. Here is a simple guide:

Waste Material Type | Required Baler Features and Considerations |

Cardboard and Paper | Big, strong balers with auto-tie for lots of waste; tight bales are easy to move. |

Plastics | Balers with tools for film plastics; automatic balers help with steady waste and strong pressing. |

Metal Waste | Tough balers with extra support and strong pressing power. |

Specialty Materials | Special balers for foam, textiles, or tires to help with pressing problems. |

Pick a baler that works best for your main waste. It should also help your waste plan.

Volume and Frequency

Think about how much waste you make and how often. Do you fill bins every day or just sometimes? Horizontal balers are good for places with lots of waste all the time. If you make at least 2 tons of waste each day, a horizontal baler is a good choice. Some places handle hundreds of tons every day. Fully automatic balers are best for busy places. Manual or semi-automatic balers work for smaller or less busy places. The right baler helps keep your work easy and your space neat.

Tip: Automatic loading systems can help you work faster and handle more waste.

Fluctuations

Waste does not always stay the same. Sometimes you have more waste during busy times. Other times, you have less. Factories and warehouses often see changes from making too much, storing, or moving things. To be ready, look at your old data and watch for changes. You can change your plan, rent more machines when it gets busy, and teach your team what to do. Make sure your baler can handle your busiest times, not just normal days. Keep your baler in good shape so it works when you need it.

Watch your waste and check for short-term changes.

Get ready for busy times and pick a baler that can keep up.

Talk to recycling partners about what kind of bales they want.

Fix your baler before busy times start.

Facility Needs

Space and Layout

Look at your space before picking a horizontal baler. Horizontal balers are bigger than vertical ones. You need enough room for the machine and people. Make sure the baler does not block walkways. It should not block work areas. Put the baler near where you keep recyclables. This saves time and helps your team work better.

Check if the floor is strong and stable, like concrete.

Put the baler where your team can reach it easily.

If the baler is outside, cover it with a roof or canopy.

Tip: Keep space open around the baler. This helps stop accidents and makes fixing the baler easier.

Installation

Setting up your baler needs planning. Your team should know how to use it safely. Train everyone on loading and daily checks. Make a schedule for regular maintenance. Check the hydraulic system often. Lubricate moving parts and replace old pieces.

Load materials evenly to stop jams.

Do not put too much in the baler. This helps it last longer.

Sort materials and take out staples or bindings.

Safety First: Everyone should wear gloves, safety glasses, and steel-toed boots. Keep the area around the baler clear. Check all safety features before using the baler.

Future Growth

Think about how your waste might change. Your business could grow or add new products. Plan for more waste now. This way, you will not need a new baler soon. Look at your waste now and guess how much it could go up.

Use your data to find trends.

Think about smart baling systems with sensors.

Add automated conveyors or collection points as you grow.

Planning ahead helps you work well and be ready for changes.

Choosing a Horizontal Baler

Key Features

When you pick a baler, look for features that help your work. The right equipment saves time, money, and effort. Here are some things to check:

Hopper Design: A wide, funnel-shaped opening lets you load fast. The Huanhong Horizontal Baler has a big feed opening. You can put in large items like cardboard and plastics easily.

Shear Blade System: This part cuts big materials and keeps the machine working well. You want a system that is strong and simple to adjust.

Compression Chamber: Look for solid steel with no seams. This helps the baler handle high pressure and last longer.

Ram or Platen: This part pushes and squeezes your waste. Good hydraulic rams make better, tighter bales.

Bale Tying: You can pick manual or automatic tying. Automatic tying saves time and keeps bales tight.

Ejection System: Automatic bale ejection makes your work faster and keeps things moving.

Operator Safety: Make sure your baler has safety features like locks and emergency stops.

Maintenance and Support: Easy access for repairs and good support help you avoid problems.

Tip: Features like automatic loading, smart controls, and sensors can help you work faster. The Huanhong Horizontal Baler has these options. It is a smart pick for big recycling jobs.

Compression Force

Compression force is very important when picking a baler. This is the power that squeezes your waste into tight bales. Modern horizontal balers use hydraulic systems for this. They can make forces from 20 tons up to 300 tons. Most balers for recycling use between 100 and 250 tons of force. The Huanhong Horizontal Baler gives strong compression. You get even bales every time.

Why does this matter? More compression force means denser bales. Dense bales take up less space and are easier to move. You can fit more bales on a truck. This lowers transport costs. Studies show dense bales can cut shipping costs by up to 70%. If you handle cardboard, plastics, or metals, you need a baler that keeps up. It should make bales that meet recycling center rules.

Note: Always match the compression force to your main waste. Too little force makes loose bales. Too much can break the machine or waste energy.

Build Quality

Build quality makes some balers better than others. You want a horizontal baler that can handle heavy use every day. The Huanhong Horizontal Baler uses strong steel and good hydraulic parts. This means it lasts longer and needs fewer repairs.

Look for these signs of good build quality:

Solid steel frames and strong stress points

Tough welds and plates that fit together well

Heavy-duty motors and safe electrical panels

Safety features like door locks and warning labels

A well-built baler breaks down less and costs less to fix. Regular checks and care help your baler last longer. When you pick a baler with good build quality, you get smooth work and peace of mind.

Remember: Good build quality keeps your baler running. It also keeps your team safe and your work steady.

Picking the right baler means looking at all these features. The Huanhong Horizontal Baler has high throughput, a wide feed opening, strong compression, and good build quality. These things help you handle many types of waste. They keep your recycling work easy and save money.

Baler for Your Facility

Matching Needs

You want a baler for your facility that fits your waste stream and daily operations. Start by looking at what you throw away most. Do you handle mostly cardboard, plastics, or metals? Each material needs a different approach. Next, check how much waste you create every day or week. If you have a high volume, you need a heavy-duty baler with strong compression and automation features. Lower volumes may work with a smaller model.

Here’s a quick checklist to help you match the right baler for your facility:

Material Type: Choose a baler that handles your main waste, like cardboard, plastics, or metals.

Waste Volume: Pick a size and power level that matches how much waste you generate.

Available Space: Make sure you have enough room for the baler and safe operation.

Automation: Look for features like auto-tie, bale ejection, and smart controls to save time and labor.

Maintenance: Select a model that is easy to maintain and built to last.

You can also talk with baler experts to review your needs. They can help you pick the best model for your waste type and volume. Regular checks and training keep your baler running smoothly and safely.

Tip: Always plan for future growth. If your business expands, your waste output may increase. Choose a baler that can handle more if needed.

Placement

Where you put your baler for your facility matters a lot. Good placement keeps your team safe and your workflow smooth. Place the baler close to where you collect waste. This cuts down on the time and effort needed to move materials. You also reduce clutter and trip hazards.

Here are some key points to consider:

Place the baler near waste collection points to save time and lower labor costs.

Keep the area around the baler clear to avoid accidents and fire risks.

Make sure the floor is strong enough to support the machine.

Allow enough space for loading, unloading, and maintenance.

When you use a baler, you turn loose waste into neat, compact bales. This frees up floor space and makes your facility look cleaner. Uniform bales stack safely and reduce the risk of accidents. Automation features, like auto-tie and bale ejection, also help your team work faster and safer.

Safety Alert: Always check that safety guards and emergency stops are easy to reach. Train your team to use the baler safely every time.

Integration

You want your baler for your facility to work well with your current waste management system. Start by checking what types and amounts of waste you handle. Make sure the baler can process these materials without problems. Think about how the baler will fit into your workflow. Will it connect to a conveyor or shredding system? Does it need to work with other machines?

Here’s what to look for when integrating a baler:

Check that the baler’s capacity matches your waste output to avoid slowdowns.

Make sure the baler fits your space and layout for smooth operations.

Decide if you need manual or automatic operation based on your team and workload.

Look for safety features like interlocks and emergency stops.

Plan for regular maintenance to keep the baler running well.

Review your budget and think about long-term savings from automation and efficiency.

Make sure the baler meets all safety and environmental rules.

Smart balers with IoT sensors and automation can help you track performance and spot problems early. This keeps your system running and helps you meet recycling goals. When you plan carefully, you get a baler that fits your needs, saves money, and keeps your team safe.

Note: Always check if your baler can grow with your business. Modular designs and smart features make upgrades easier in the future.

Comparing Baler Types

Open-End vs Closed-End

There are different types of balers you can pick. Two main kinds are open-end and closed-end horizontal balers. Each one works best for certain waste and places. Let’s see how they are different:

Feature | Open-End Balers | Closed-End Balers |

Operation Mode | Runs all the time and ties bales by itself | Works in batches and needs people to help tie and push out bales |

Throughput | Handles many tons each hour, good for lots of waste | Makes up to 3 bales an hour, better for less or on-and-off waste |

Bale Density | Makes very tight bales by pressing waste all the time | Makes tight bales too, best for hard or heavy waste, presses hard in short times |

Material Handling | Great for things like cardboard, shrink wrap, and mixed paper | Best for hard, heavy waste like plastics and metals; easy to switch between waste types |

Automation | Ties bales by itself, so you do less work | Usually needs people to tie and push out bales |

Suitability | Best for places with lots of the same waste all day | Good for places with different waste types or not much waste |

Open-end balers are good if you always have lots of cardboard or paper. They keep working and tie bales without help. Closed-end balers are better for smaller places or where you have many kinds of waste. You can change what you put in them fast and handle tough or heavy things easily.

Tip: If your waste changes a lot, closed-end balers make it easy to switch what you are baling.

Auto-Tie Horizontal Baler

If you want to save time and do less work by hand, pick an auto-tie horizontal baler. This baler ties each bale by itself, so your team does not need to do it. Here is why big recycling centers and busy places like this kind of baler:

You do not need to tie bales by hand, so you work less.

You can bale more waste faster, which helps you get more done.

Each bale is tight and small, so it is easy to store and move.

It is safer because there is less loose waste and fewer accidents.

You can follow recycling rules better with neat bales.

You can use it for many kinds of waste, like cardboard, plastics, and metals.

An auto-tie horizontal baler is best for places with lots of waste and steady work. If your business is getting bigger or you want to make recycling easier, this baler gives you speed, safety, and good results.

Note: Auto-tie horizontal balers help you keep up with busy times and make recycling easier.

Operational Considerations

Throughput

You want your baling equipment to keep up with your waste flow. Throughput tells you how much material your baler can handle in a set time. Some balers process less than a ton per cycle, while others handle up to 10 tons. Take a look at this table to see how different balers compare:

Baler Type | Capacity per Cycle (tons) | Typical Material | Bale Size |

Small Cardboard Baler | 0.5 - 1 | Cardboard | Small |

Mid-Range Cardboard Baler | 2 - 3 | Cardboard, Plastics | Medium |

High-Capacity Cardboard Baler | 5 - 10 | Cardboard, Mixed Waste | Large |

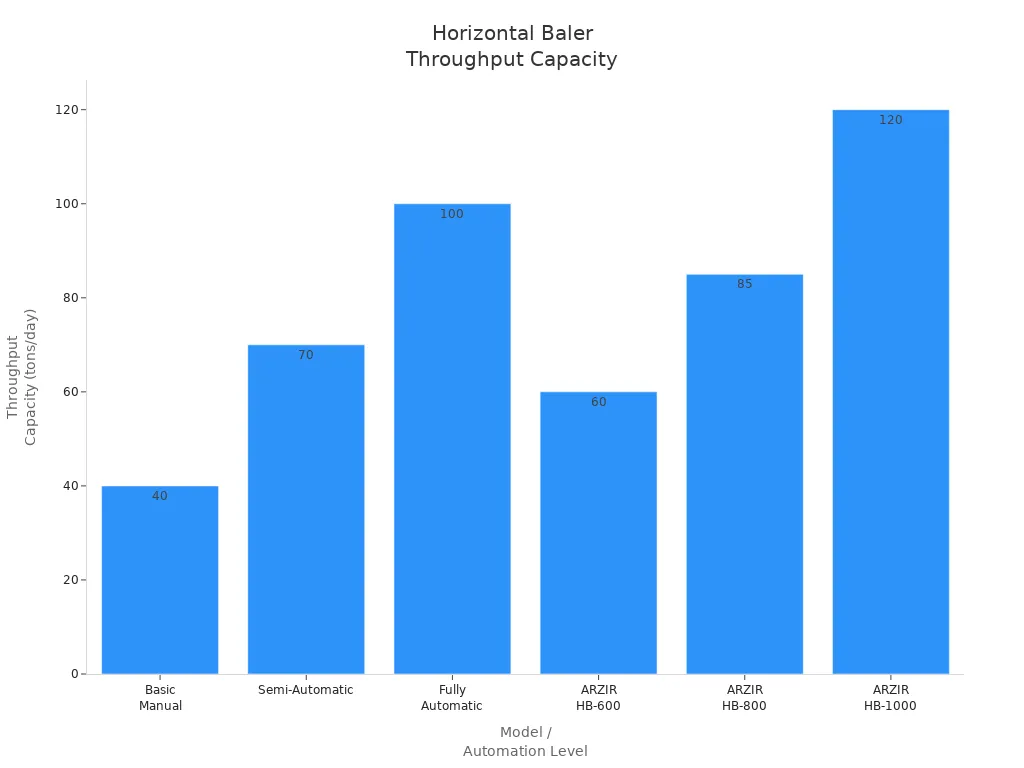

If your facility handles a lot of waste, you need a baler with high production capacity. Automation also plays a big role. Check out this chart to see how throughput jumps as you move from manual to fully automatic models:

Labor

Labor is a big part of your daily costs. The right baler can help you save time and effort. Manual balers need more hands-on work. Automatic balers do most of the job for you. Here’s a quick list of what you get with more automation:

Less time spent loading and tying bales

Fewer workers needed for each shift

More time for your team to focus on other tasks

You can boost your team’s productivity and cut down on overtime.

Maintenance

Keeping your baler in top shape means fewer breakdowns and more uptime. You should check the hydraulic system, clean moving parts, and replace worn pieces often. Make a simple checklist for your team:

Inspect for leaks or odd noises

Lubricate all moving parts

Test safety switches and emergency stops

Tip: Schedule regular maintenance to avoid costly repairs and keep your baler running smoothly.

Safety

Safety always comes first. You want your team to stay safe while using heavy machinery. Make sure everyone gets proper training. Use safety gear like gloves and goggles. Keep the area around the baler clear. Always check that guards and emergency stops work before starting the machine.

Remember: A safe workspace means fewer accidents and a happier team.

Choosing a Baler Supplier

Cost and ROI

When you start choosing a baler, you want to know if your investment will pay off. You can look at both the upfront price and the long-term savings. Here’s how many facilities check the return on investment (ROI):

Compare the purchase price with how much you save on labor and time.

See how automation can cut down on manual work and boost bale quality.

Add up savings from fewer waste pickups and lower hauling fees.

Check if you can make money by selling dense, high-quality bales.

Think about the cost of maintenance and how long the baler will last.

Some companies try a rental first. One distribution center rented a horizontal baler for a year. After seeing big savings, they bought three balers. Their investment paid off in less than a year because they saved on hauling and made money from selling bales. You can use this kind of plan to test what works best for your facility.

Support and Training

You want a supplier who stands by you after the sale. Good support means you get help fast if something goes wrong. Training is just as important. Your team should know how to use the baler safely and keep it running well. Look for suppliers who offer:

On-site setup and training for your staff

Easy-to-follow guides and videos

Quick answers to service calls

Regular maintenance plans

Tip: Well-trained teams make fewer mistakes and keep your baler working longer.

Supplier Reputation

A trusted supplier makes your job easier. You want a company with a strong track record. Check reviews and ask other businesses about their experience. A good supplier will answer your questions and help you pick the right baler for your needs. They should offer expert advice and even visit your site to see what works best.

What to Look For | Why It Matters |

Positive customer reviews | Shows reliability and trust |

Fast response times | Reduces downtime |

Expert advice | Helps you choose the right model |

Ongoing support | Keeps your baler running |

Note: Don’t be afraid to ask for references or case studies. The right supplier will be happy to share success stories.

Choosing the right horizontal baler helps your facility run smoother and saves money. Use the steps in this guide as your checklist. Think about your waste, your space, and your team’s needs. If you want expert advice or a custom quote, reach out to Huanhong. Our team can help you find the perfect baler for your business. Ready to take the next step? Contact us today for more information!

FAQ

How do I know which horizontal baler size fits my facility?

First, look at how much waste you make each day. Check what kinds of materials you throw away most. Measure the space you have for a baler. If you are not sure, you can ask an expert to visit your site. Picking the right size helps your work stay easy and your space neat.

Can I use a horizontal baler for different materials?

Yes, you can use it for many things. Horizontal balers can handle cardboard, plastics, and metals. Some balers work better with certain materials than others. Always read the baler’s details to make sure it fits your main waste.

How much maintenance does a horizontal baler need?

You should look at your baler every day. Watch for leaks, strange sounds, or broken parts. Clean and oil the moving parts often. Plan for regular checkups by a professional to keep your baler safe and working well.

Is training required to operate a horizontal baler?

Yes, training is needed. Your team must learn how to load waste and use safety tools. They should also know how to do simple checks. Good training stops accidents and keeps your baler working its best.

What are the main benefits of using a horizontal baler?

You save space and need less work to handle waste. Baled waste is easier to store and move. You can also pay less for hauling and make recycling better.