The right baler for your business depends on how much waste you have, how much space you have, your budget, and what your business needs. If your business is small or medium and does not have much space or waste, a vertical baler is usually the best choice. Big businesses with lots of waste often need a horizontal baler because it works faster and better.

Factor | Vertical Balers | Horizontal Balers |

Space Requirements | Takes up less space, good for small areas | Needs more room, takes up more floor space |

Cost | Costs less to buy and run | Costs more to buy and keep working |

Volume of Materials | Good for small amounts of waste | Best for lots of waste |

Automation | Needs more people to work it | Often runs by itself, so fewer workers needed |

Capacity & Throughput | Holds less waste | Holds and processes more waste |

Key Takeaways

Pick a vertical baler if your business has little or medium waste. It is good if you do not have much space. It saves money and fits in small places.

Choose a horizontal baler if you have lots of waste and a big area. It works faster and needs fewer workers. It makes bigger and heavier bales.

Think about how much waste you have each day. Look at your space, money, and what you need to bale. This helps you pick the right baler for your business.

Horizontal balers with automation are safer. They cost less for workers and work better than manual vertical balers.

Use the checklist to check your waste, space, money, and materials. Do this before you pick a baler. It will help you save money and work better.

Horizontal Baler vs Vertical Baler

What is a Horizontal Baler?

A horizontal baler is a big machine for lots of waste. You put things like cardboard or plastic inside. Most times, you use a conveyor belt or tipper to feed it. The machine squashes the waste sideways. It makes big, heavy bales. Most horizontal balers work by themselves. They tie up the bales and push them out. You do not need to help much. This baler is good for recycling centers or factories. These places have lots of waste every day. It works fast and saves time. You also save on labor.

What is a Vertical Baler?

A vertical baler is a small machine for tight spaces. You put waste in from the top by hand. The machine pushes the waste down with a ram. When it is done, you tie the bale yourself. You also take it out on your own. Vertical balers are good for small stores, offices, or warehouses. You do not need much room. You can handle a medium amount of waste. This baler costs less money. It is simple to set up.

Key Differences

Here are the main differences between horizontal and vertical balers:

Feature | Vertical Balers | Horizontal Balers |

Footprint | Small, needs tall space | Big, needs lots of floor space |

Throughput | 1-5 bales each day | Many tons per hour, keeps working |

Feeding Method | You load by hand | Uses machines to load waste |

Automation Level | You tie and remove bales | Ties and removes bales by itself |

Bale Size & Weight | Smaller, lighter, different densities | Bigger, heavier, same high density |

Labor Requirement | Needs more work for each bale | Needs less work for each bale |

Tip: If you have less than 8 tons of waste each day and not much space, pick a vertical baler. If you have 18 to 60 tons daily and want to use less labor, a horizontal baler is best for you.

Waste Volume

Low to Moderate Volume: Vertical Balers

If you run a small store or office, you may not have much waste. A vertical baler is often the best choice for you. It works well when you have a little or medium amount of waste. You put materials in by hand. The machine squeezes them into smaller bales. These bales can be between 25 and 200 cubic feet. The size depends on the model you use. Most vertical balers make bales that weigh up to 2,000 pounds. Many bales are lighter than that.

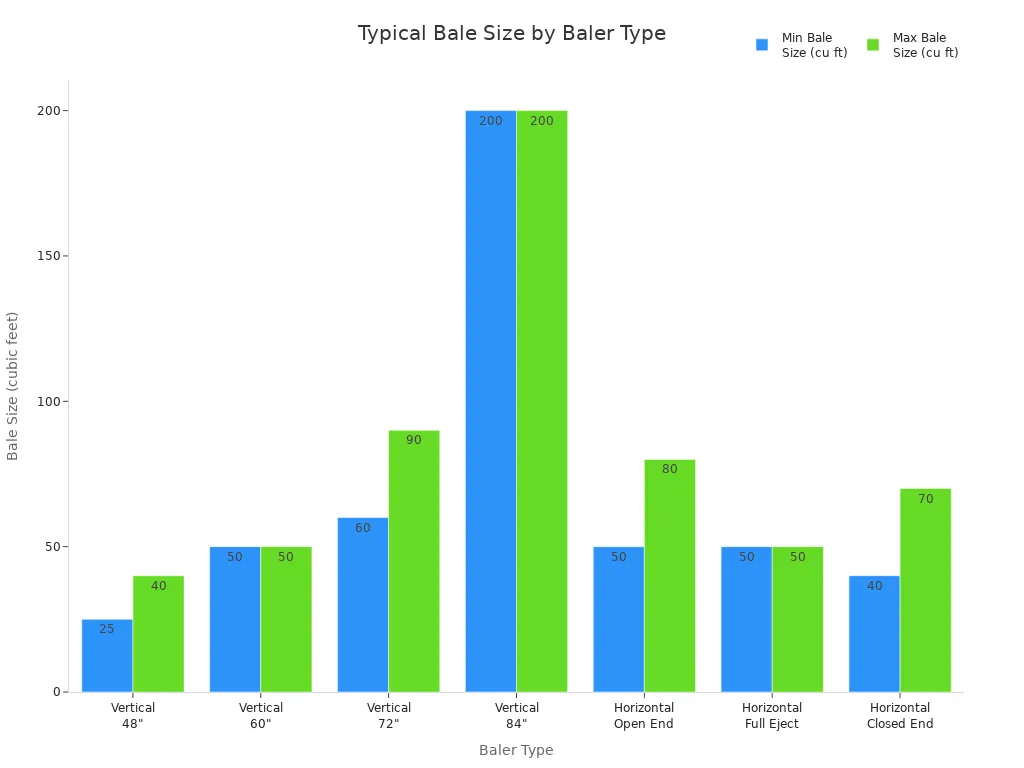

Here is a simple chart showing bale sizes and weights for vertical balers:

Baler Type | Typical Bale Size (cubic feet) | Typical Bale Weight (lbs) | Notes on Volume Handling and Usage |

Vertical Balers (48") | 25 - 40 | Up to ~1,100 | Small bales, good for small stores and less waste |

Vertical Balers (60") | ~50 | Up to ~2,000 | Medium bales, still for small businesses |

Vertical Balers (72") | 60 - 90 | Up to ~2,000 | Bigger vertical balers, but still smaller than horizontal |

Vertical Balers (84") | Up to 200 | Up to ~2,000 | Largest vertical balers, biggest size for this type |

If your business makes only a few bales each day, a vertical baler saves you space and money. You can use it for cardboard, plastic, and other things you recycle. You do not need a big machine. Vertical balers are smart for places with little room and less waste.

High Volume: Horizontal Balers

If your business makes a lot of waste every day, you need a baler that works fast. Horizontal balers are good for big amounts of waste. These machines can take in waste all the time and work quickly. Horizontal balers make bales between 40 and 80 cubic feet. The bales can weigh up to 2,000 pounds. Some models can handle up to 25 tons of waste every hour.

Baler Type | Typical Bale Size (cubic feet) | Typical Bale Weight (lbs) | Notes on Volume Handling and Usage |

Horizontal Balers (Open End) | 50 - 80 | Up to ~2,000 | Made for very high waste, keeps working, up to 25 tons/hour |

Horizontal Balers (Full Eject) | ~50 | Up to ~2,000 | Good for lots of different materials |

Horizontal Balers (Closed End) | 40 - 70 | Up to ~2,000 | Works all the time, up to 20 tons per shift, best for big jobs |

You should pick a horizontal baler if you make more than 4,000 pounds of waste each day. These balers are made for factories, warehouses, and recycling centers. They work fast and do a lot of the work for you. Horizontal balers help you save time and need fewer workers. They are great for businesses that have lots of waste to manage.

Tip: Always choose a baler that matches how much waste you make each day. This helps you save money and makes sure your machine can keep up.

Space Requirements

Vertical Baler: Small Footprint

If you have a small space, you need equipment that fits. A vertical baler does not take up much room. You can put it in tight spots. It can go next to a wall or under a low ceiling. Many vertical balers have sliding doors. You do not need extra space to load waste. This makes it easy to use in narrow rooms or corners. It will not block walkways.

Small businesses like vertical balers because they save space. You can keep your work area neat. You do not have to move other machines. If you own a store or a small warehouse, a vertical baler fits in your backroom or storeroom.

Here is a table that shows the size of a vertical baler:

Vertical Baler Model | Height (inches) | Width (inches) | Depth (inches) | Depth with Door Open (inches) |

PeeWee Baler (example) | 77 | 33 | 29 | 56 |

Tip: You can put a vertical baler in places with little space. This helps you handle waste without changing your setup.

Horizontal Baler: Large Footprint

A horizontal baler needs a lot more room. You must plan for the machine and space for loading and bale removal. These balers use conveyor belts or tippers. That means you need even more space. You may need a special area or a separate room.

If your business has lots of waste, you need a horizontal baler. This baler is best for big warehouses or recycling centers. Make sure you have enough floor space before you buy one. Horizontal balers are not good for small businesses with little space.

Horizontal balers need a lot of floor space to work.

You need extra space for feeding and taking out bales.

These machines are best for places built for heavy work.

Note: Always check your space before you buy a baler. Picking the right one helps you avoid spending money to change your building.

Budget

Vertical Baler: Lower Cost

A vertical baler costs less to buy at first. It is cheaper than a horizontal baler. Many small businesses pick it because it fits their budget. You can see the price range in this table:

Baler Type | Average Purchase Price Range |

Vertical Balers | $5,000 - $20,000 |

Horizontal Balers | $20,000 - $100,000 |

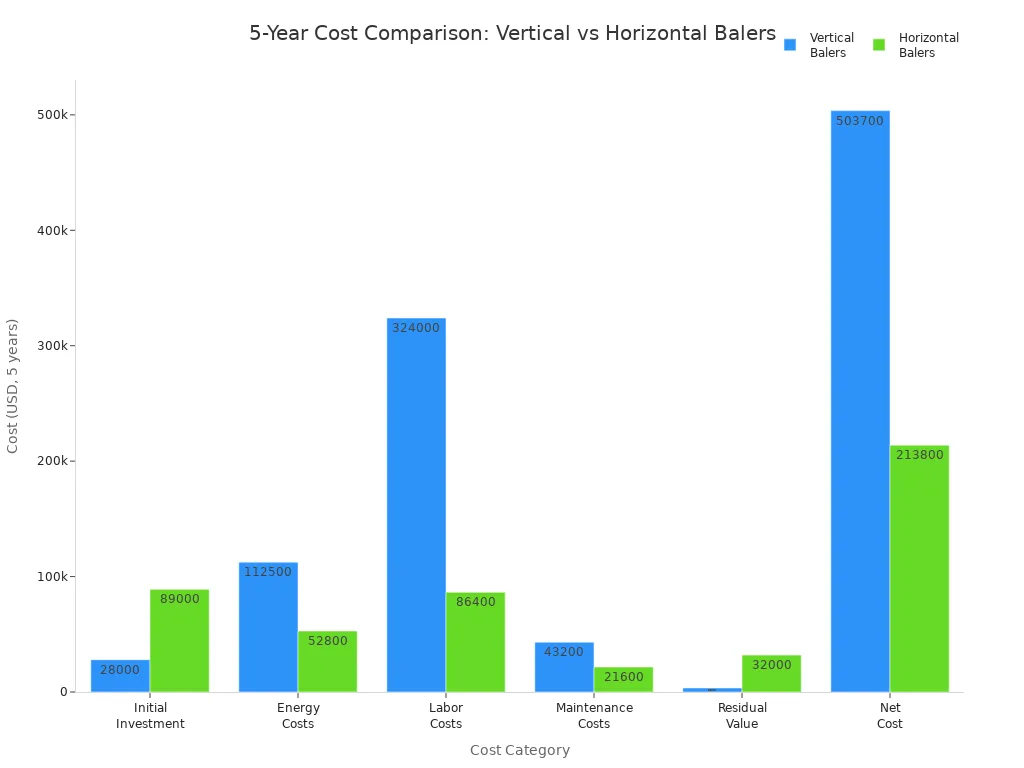

It is also cheaper to set up a vertical baler. You do not need special tools or a big area. But you should think about more than just the price. Over time, vertical balers use more power and need more people to run. They also need repairs more often, which costs more money. If you have a small store or office, a vertical baler helps you recycle without spending a lot.

Note: When you plan your budget, remember to add costs for power, workers, and repairs. These costs can grow over the years.

Horizontal Baler: Higher Investment

A horizontal baler costs more to buy at the start. The price can be $20,000 for a simple one or $100,000 for a fancy one. This is a lot, but it can save you money later. It uses less power for each ton of waste. You also need fewer workers to use it. It does not need repairs as often, so you save on fixing it.

In five years, a horizontal baler can help you save money. You pay less for workers because it works by itself. Your power bills are lower, and the machine keeps its value longer. If you have a big warehouse or recycling center, this is a good choice. When you think about price, look at both the first cost and the money you save later.

Tip: A horizontal baler is smart for big businesses that want to save money and work better.

Operational Needs

Manual Operation: Vertical Balers

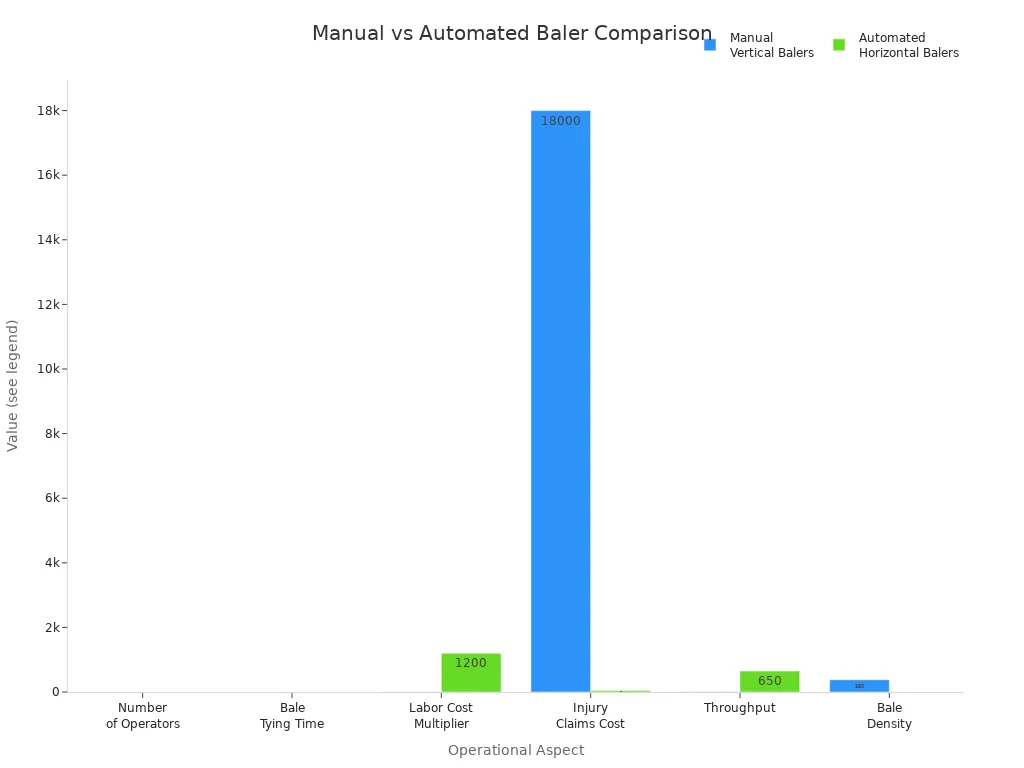

When you use a vertical baler, you do most things by hand. You put in the materials yourself. You use the controls and tie each bale. This means you need more workers to help. Usually, two or three people work together on these balers. Tying each bale takes about three to five minutes. If you make lots of bales, this time adds up fast. Because it takes longer, you pay more for workers.

Safety is also important. Most injuries with vertical balers happen when tying bales. Workers can hurt their hands or fingers if they hurry or are not careful. About 72% of injuries with manual balers happen during tying. You should train your team and use safety gear to help keep everyone safe.

Here is a table that shows how manual vertical balers and automated horizontal balers compare:

Aspect | Manual Vertical Balers | Automated Horizontal Balers |

Number of Operators | 2-3 operators | 1 operator |

Bale Tying Time | 3-5 minutes per bale (manual tying) | 18-35 seconds per bale (automatic tying) |

Labor Cost Multiplier | 6-9 times higher labor costs | Baseline |

Percentage of Injuries During Tying | 72% of manual baler injuries occur during tying | 92% reduction in workplace hand injuries due to robotic tie systems |

Labor Reduction | Baseline | Up to 90% labor reduction |

Jam Prevention | N/A | Intelligent sensors prevent 78% of jams |

Throughput | 2-8 tons/day | 20-80 tons/day |

Bale Density | 380 kg/m³ | 650 kg/m³ |

Overtime Labor Cost (Example) | $23,000 in peak season | Significantly reduced |

5-Year Labor Cost (10T/day) | $216,000 | $28,800 |

5-Year Injury Claims Cost | $18,000 | $1,200 |

Operational Downtime | Higher | <2% downtime |

Tip: Vertical balers are best for small businesses with steady, low waste. You can keep your area clean and handle waste as it comes. But you need to plan for more workers and teach them to be safe.

Automated Efficiency: Horizontal Balers

A horizontal baler uses machines to help you work faster. You load waste with a conveyor or tipper. The machine presses and ties each bale by itself. One person can run the whole system. This makes things quicker and saves money on workers. Each bale is tied in just 18 to 35 seconds.

Horizontal balers also help keep workers safe. Robotic tie systems lower hand injuries by 92%. Smart sensors stop jams, so you have less downtime. You can process up to 80 tons of waste every day. This means you can handle a lot of waste quickly.

You save a lot of money over time. For example, if you handle 10 tons of waste each day, your five-year labor cost drops from $216,000 with vertical balers to $28,800 with horizontal balers. You also spend less on injury claims, which keeps your team healthy and saves money.

Note: If your business needs to handle heavy, dense, or lots of waste, a horizontal baler is best. Automation helps you work faster, keeps workers safe, and gets more done.

Material Types

Cardboard Baler Options

Many businesses have lots of cardboard boxes and packaging. Picking the right cardboard baler makes handling this waste easier. Vertical balers are good for small or medium businesses. You can put cardboard in by hand. The machine makes neat bales you can stack. These bales meet recycling rules and help keep your area clean. If you have a lot of cardboard, a horizontal baler is better. It uses a conveyor or hopper to load lots of cardboard at once. The machine presses the cardboard into tight, heavy bales. This saves you time and means you need fewer workers.

Here is a table to help you pick the best baler for cardboard:

Baler Type | Most Efficient Materials | Suitable Applications | Bale Characteristics | Additional Notes |

Vertical Balers | Cardboard, paper, lightweight plastics, foam | Retail stores, offices, small warehouses | Dense, uniform bales | Space-saving, cost-effective for moderate volumes |

Horizontal Balers | Cardboard, paper, plastics, metals | Recycling centers, factories, large warehouses | Larger, heavier bales | Handles higher volumes of recyclables efficiently |

Tip: If you have small amounts of cardboard, use a vertical baler. For bigger jobs, a horizontal baler does more work with less effort.

Other Recyclables

You might also need to recycle things like plastics, metals, or textiles. Vertical balers can handle plastic bottles, cans, and some metals. These machines make bales that can weigh up to 1,645 pounds. You put the materials in from the top and tie the bales yourself. This helps keep the bales clean and works well for mixed waste.

Horizontal balers can handle more types of materials. You can use them for plastics, metals, textiles, and rubber. They load and tie bales by themselves, which keeps the bales cleaner. These machines make strong, even bales. This is great for businesses with lots of recyclables.

Note: Using wire or plastic straps helps keep bales safe from water and bugs. This keeps your recyclables clean when you move them.

Pros and Cons

Vertical Balers: Pros & Cons

A vertical baler is good for small or medium businesses. It fits in small spaces and costs less than bigger machines. You can use it for cardboard, paper, and light plastics. The design is simple, so it is easy to use and fix. Safety features like emergency stop buttons help keep you safe. Two-handed controls also protect you and your team. The doors are strong and help keep everyone safe while using the machine.

But a vertical baler only handles small amounts of waste. You have to load materials and tie bales by hand, which takes more time. The bales are smaller, so they might not meet all recycling rules. If your business gets bigger, you may need a larger machine.

Pros:

Saves space in small areas

Lower purchase and maintenance costs

Simple to use and maintain

Strong safety features

Cons:

Horizontal Balers: Pros & Cons

A horizontal baler is best for big businesses with lots of waste. This machine can handle large amounts quickly. You can load waste with a conveyor, which saves time and work. The bales are bigger and heavier, so they are easier to move and sell. Automation means you need fewer workers. You can add extra features like shredders for more help.

But a horizontal baler needs a lot more space. It costs more to buy and keep working. The machine is big, so it may not fit in every business. You need to plan your space before getting one.

Pros:

Handles large volumes efficiently

Automated features reduce labor

Produces large, dense bales

Can process a wide range of materials

Cons:

Feature/Aspect | Vertical Balers | Horizontal Balers |

Space Requirements | Compact, fits small spaces | Needs much more floor space |

Capacity | Best for small to medium waste volumes | Designed for high-volume operations |

Bale Size | Smaller, easier to handle | Larger, denser bales |

Operation | Simple, manual operation | Automated, less manual work |

Cost | Lower purchase and upkeep | Higher purchase and upkeep |

Labor | More manual labor needed | Less labor due to automation |

Suitability | Small to medium businesses | Large businesses with lots of waste |

Choosing the Right Baler

Picking the right waste baler can seem hard. You can make it easy by using a simple checklist. This section will help you step by step. You will find the best baler for your needs.

Assess Waste Volume

First, look at how much waste you make each day. This helps you pick the right baler size and type.

Count how much and what kind of waste you have each week.

Write down if your waste is mostly cardboard, plastic, or mixed.

Guess your daily or weekly waste in pounds or tons.

Think about busy times when you make more waste.

Decide if your waste is low (less than 2 tons/day), moderate (2–4 tons/day), or high (over 4 tons/day).

Use this info to help choose your baler.

Tip: If you have lots of waste, you need a bigger, stronger machine. If you have light waste or only a few bales, a smaller baler is fine.

Measure Space

You must check if you have enough room for your baler.

Measure the space where you want to put the baler.

Check the ceiling height if you want a vertical baler.

Make sure the floor can hold the baler's weight.

Look at your workspace layout. The baler should not block doors or walkways.

Think about how you will move waste to the baler and take bales out.

Check if you can get to loading docks or storage easily.

Review electrical and safety needs for setup.

Note: Vertical balers fit in small spaces. Horizontal balers need more room and a clear path for loading and unloading.

Set Budget

Setting a budget helps you pick a baler you can afford.

Add up all costs, not just the price to buy. Include delivery, setup, training, and installation.

Think about costs like electricity, repairs, and supplies.

Plan for fixing and spare parts to keep your baler working.

Ask about warranties and training for your team.

Leasing or renting can help lower upfront costs.

Make sure your baler meets safety rules and your staff knows how to use it.

Tip: A good budget looks at the total cost over the baler's life, not just the price.

Review Materials

Check what materials you need to bale. This helps you pick the best machine for your waste.

Write down the main things you recycle, like cardboard, plastics, or metals.

See if you need to sort materials before baling.

Think about how much space you need to store bales.

Make sure the baler can handle your usual bale size and weight.

Think about how baling changes your waste pickup and costs.

Pick a baler style that fits your materials and space.

Safety first: Teach your team to use the baler safely, especially with heavy or sharp waste.

Match to Business Type

Every business is different. Here are some examples to help you choose:

Business Type | Best Baler Type | Typical Bale Weight (lbs) | Key Features and Benefits |

Small Retail Store | Small vertical baler | 85–290 | Fits tight spaces, easy to use, no forklift needed, handles low waste volumes |

Medium Warehouse | Medium/large vertical baler | 440–1,300 | Makes heavier bales, works with forklifts, wide feed opening, reduces pickups |

Large-Scale Operation | Heavy-duty vertical or horizontal baler (e.g., Huanhong Horizontal Baler) | 1,550–1,850+ | High throughput, automatic feeding and tying, large bale chamber, cuts labor and costs |

If you own a small shop, a compact vertical baler saves space and is easy.

If you run a warehouse, a bigger vertical baler handles more waste and makes larger bales.

If you work at a recycling center or big facility, pick a horizontal baler. The Huanhong Horizontal Baler is great for lots of waste. It feeds waste automatically, presses hard, and ties bales fast. It is good for businesses with lots of cardboard, plastics, or mixed recyclables.

Remember: Picking the right baler for your business size and waste amount saves money, helps work go smoothly, and keeps your workplace safe.

Step-by-Step Checklist: How to Choose the Right Waste Baler

Measure your daily or weekly waste.

List the main materials you need to bale.

Measure your floor and ceiling space.

Set a budget and include all costs.

Decide if you want manual or automatic operation.

Match your business type to the right baler size and features.

Check for safety features and staff training.

Pick a trusted supplier who offers support and maintenance.

If you follow these steps, you will know how to pick the right waste baler for your business.

Huanhong Horizontal Baler

Product Overview

If your business has lots of recycling waste every day, you need a strong baler. The Huanhong Horizontal Baler is made for big jobs. It has a wide opening, so you can load lots of cardboard, plastics, or mixed recyclables fast. Its strong ram pushes the waste sideways and makes tight, even bales. This machine works well in busy places like factories, warehouses, or recycling centers.

The Huanhong Horizontal Baler uses smart automation. It loads waste, ties bales, and lets you check it from far away. These features help you save time and do less work by hand. Many companies pay less for workers and have safer workplaces after using this baler.

Key Features

You want a baler that is as good as or better than others. The Huanhong Horizontal Baler does well in all important ways:

Performance Aspect | Huanhong Horizontal Baler Benefits | Industry Standard Comparison |

Throughput | Handles lots of waste with automatic loading and pressing | As good as or better than top machines |

Bale Quality | Makes big, tight bales that are easy to move | Same as the best recycling machines |

Automation | Loads, ties, and controls bales by itself | Needs fewer workers and is safer |

Energy Efficiency | Uses less power with special drives | Saves energy like other good machines |

Labor Requirements | Needs less hand work, just one skilled worker | Costs less for big jobs |

Safety | Automation helps keep workers safe | Makes the workplace safer |

Environmental Impact | Tight bales mean fewer trucks and less pollution | Helps protect the environment |

Tip: Picking the Huanhong Horizontal Baler helps your business work better, saves money, and is good for the planet.

Choosing the right waste solution depends on your daily waste volume, available space, budget, and how your team operates. Use the checklist to match your needs with the best equipment. Regular maintenance and proper training help you get the most from your investment. For tailored advice, reach out to Huanhong. Our team can help you find the perfect fit for your business. Take the next step and contact us to discuss your needs today.

FAQ

What is the main difference between a horizontal and a vertical baler?

You put waste into a vertical baler from the top by hand. A horizontal baler uses a conveyor or hopper to load waste. Horizontal balers can handle more waste and work faster. Vertical balers are better for small spaces and cost less money.

How do I know which baler fits my business?

Look at how much waste you have each day, your space, and your budget. Small stores usually use vertical balers. Big warehouses or recycling centers need horizontal balers. Use the checklist above to help you decide.

Can I use a baler for materials other than cardboard?

Yes, you can bale plastics, paper, and some metals too. Huanhong Horizontal Balers can handle many kinds of recyclables. Always check your baler’s guide to see what materials it can bale.

How much space do I need for a horizontal baler?

You need a big, open area for a horizontal baler. Make sure there is enough room to load, unload, and use the machine safely. Measure your space before you buy one.

Why should I choose Huanhong for my baler needs?

Huanhong makes strong, high-quality balers. You get good compression, automation, and help from their team. Their machines help you save time, lower costs, and recycle better.