Introduction

Ever wondered how scrap metal is efficiently compressed for recycling? Hydraulic Scrap Metal Steel Copper Baling Press Bales are the answer. These powerful machines play a crucial role in transforming bulky metal waste into compact, manageable bales. In this post, you'll learn the basics of these balers, their significance in recycling, and an overview of the baling process.

How Hydraulic Scrap Metal Balers Work

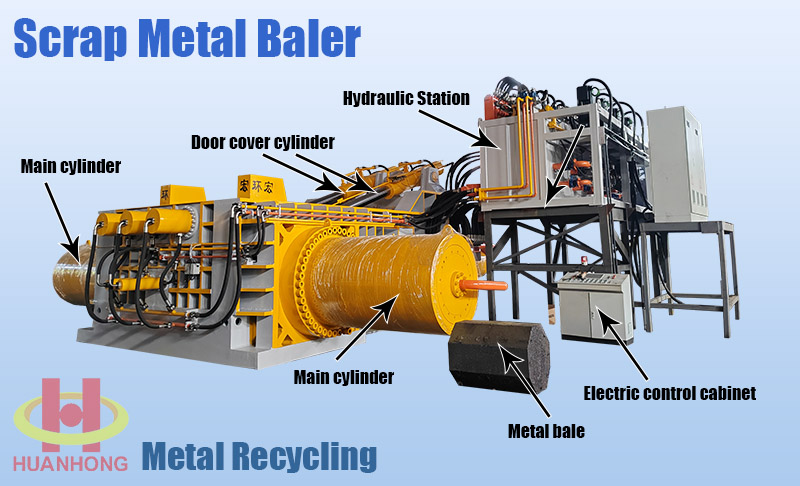

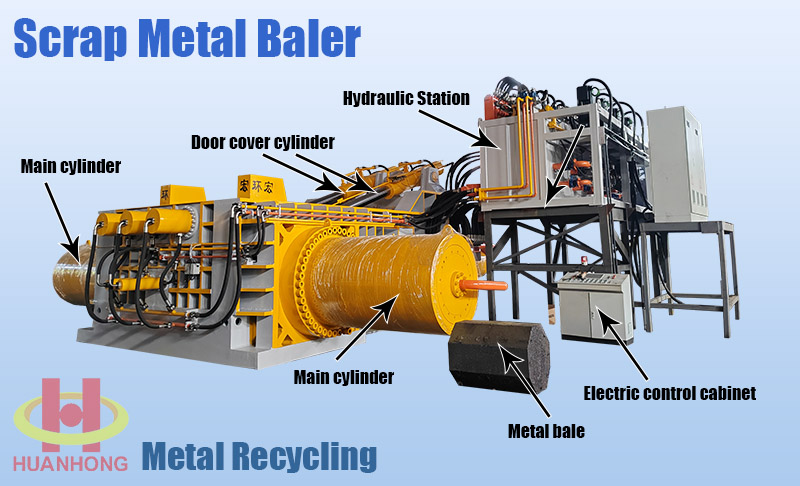

Components of a Hydraulic Baler

Hydraulic Cylinders: These provide the force needed to press metal into compact bales.

Press Box: The chamber where scrap metal is loaded and compressed.

Main Pusher: Moves forward to apply pressure and shape the bale.

Side Pusher: Assists in compressing metal from the sides for denser bales.

Door Cover: Closes the press box to form a sealed compression chamber.

Hydraulic Station: Powers the cylinders through pressurized oil.

Electric Control System: Manages the operation sequence and safety features.

Bale Discharge Mechanism: Pushes or turns the finished bale out of the press box.

Step-by-Step Baling Process

Loading: The operator feeds scrap metal into the press box.

First Compression: The door cover closes, and the top hydraulic cylinder presses down, forming the initial compression chamber.

Second Compression: The side pusher moves forward, pressing the metal from the sides.

Third Compression: The main pusher applies final pressure, holding it for a few seconds to ensure bale density.

Reset Cylinders: The top, side, and main cylinders retract to their original positions.

Bale Discharge: The bale is pushed or turned out of the press box using the discharge mechanism.

Cycle Repeat: The machine is ready for the next batch of scrap metal.

Types of Hydraulic Balers

Hydraulic balers come in various types to suit different materials and operational needs:

Side Turning Balers: The bale rotates 90 degrees to exit the press box. This method produces bales with sharp corners and is widely preferred for its bale quality.

Forward Pushing Balers: The main pusher pushes the bale straight out the front. Ideal for lightweight metals like aluminum scrap or cans.

Side Pushing Balers: The bale is pushed sideways out of the box, often onto a conveyor or truck. This method saves labor and speeds up handling.

Tip: Choose a baler type based on your scrap metal's weight and shape to maximize compression efficiency and ease of bale handling.

Advantages of Using Hydraulic Scrap Metal Balers

Efficiency and Cost-Effectiveness

Hydraulic scrap metal balers are designed to maximize efficiency in metal recycling operations. They compress large volumes of scrap metal into dense, manageable bales, reducing the space needed for storage and transportation. This compression lowers shipping costs significantly because more material fits into trucks or containers. Additionally, the high compression rate improves handling and loading times, speeding up the recycling workflow.

The hydraulic system provides strong, consistent pressure, ensuring each bale is tightly packed. This reduces the need for reprocessing or additional compression steps. The automation available in many balers cuts down labor costs by requiring fewer operators and minimizing manual handling of scrap metal. Over time, these machines deliver a strong return on investment through savings on transportation, labor, and storage.

Environmental Benefits

Using hydraulic balers supports sustainable recycling by making scrap metal recycling more practical and efficient. Compact bales reduce the volume of scrap metal waste, which means fewer trips for transportation and lower fuel consumption. This directly decreases carbon emissions associated with hauling bulky scrap.

Moreover, baled scrap metal is easier to handle for smelters and recycling plants, increasing the rate of metal recovery and reuse. This reduces the need for mining new metal ores, which is energy-intensive and environmentally damaging. By promoting a circular economy, hydraulic balers help conserve natural resources and reduce landfill waste.

Safety Features

Safety is a critical advantage of hydraulic scrap metal balers. These machines are equipped with multiple safety systems to protect operators and prevent accidents. For example, many balers include emergency stop buttons that immediately halt operation if a problem occurs.

The hydraulic system operates within controlled pressure limits to avoid overloading or mechanical failure. Protective guards and interlocks prevent access to moving parts during operation, reducing injury risks. Some models feature sensors to detect jams or abnormal pressure, triggering automatic shutdowns to protect both the machine and workers.

Additionally, quieter operation compared to mechanical balers lowers noise pollution, creating a safer and more comfortable work environment. These safety features help companies comply with occupational health regulations and reduce downtime caused by accidents.

Applications of Hydraulic Scrap Metal Balers

Industries Benefiting from Balers

Hydraulic scrap metal balers serve many industries by making scrap metal handling easier and more efficient. Steel plants rely on balers to compress scrap steel for recycling. Non-ferrous metal plants, like copper and aluminum recyclers, use balers to reduce volume and improve transport. Metal smelting factories benefit from baled scrap because it feeds their furnaces more consistently. Scrap metal recycling plants use balers daily to prepare various metals for resale or reuse. Even automotive dismantling facilities use balers to compact car shells and parts, saving space and cutting transport costs.

Types of Metals Processed

Steel: Scrap steel plates, beams, and shavings.

Copper: Copper wires, chips, and scrap pieces.

Aluminum: Aluminum cans, sheets, and alloy scraps.

Iron: Cast iron and pig iron scrap.

Other Non-Ferrous Metals: Brass, zinc, and mixed metal scraps.

Case Studies and Examples

Example 1: Steel Recycling Plant A steel recycling plant uses a side-turning hydraulic baler to compress scrap steel sheets into dense bales. This reduces storage space by 70% and lowers transport costs by fitting more bales per truckload. The dense bales also improve furnace feeding, increasing smelting efficiency.

Example 2: Non-Ferrous Metal Recycler A copper recycling facility employs a forward pushing baler to compact copper wire scraps. The baler’s adjustable pressure ensures the copper is tightly packed without damaging the material. This improves handling and shipping, boosting profits by reducing waste volume and transport fees.

Example 3: Automotive Dismantling Yard An auto scrapyard uses a hydraulic baler to compress car shells and metal parts. The baler’s robust hydraulic system handles heavy, irregular shapes, turning them into uniform bales. This simplifies storage, speeds up loading for transport, and enhances safety by reducing sharp scrap edges.

Choosing the Right Hydraulic Scrap Metal Baler

Factors to Consider

Type of Scrap Metal: Different metals require different compression forces. Heavy metals like steel or iron need high extrusion force balers. Lightweight metals such as aluminum cans or copper wires need less force.

Volume of Scrap: High-volume operations benefit from balers with faster cycle times and larger press boxes. Small-scale recyclers may prefer compact models.

Bale Size and Weight: Consider the desired bale dimensions for ease of storage, transport, and handling. Larger bales reduce transport costs but require stronger machinery.

Baling Method: Choose between side turning, forward pushing, or side pushing discharge based on your workflow and space constraints.

Automation Level: Fully automatic balers reduce labor but cost more. Manual or semi-automatic balers may suit smaller businesses.

Durability and Maintenance: Look for machines made from wear-resistant steel and with easy maintenance access to minimize downtime.

Safety Features: Ensure the baler has emergency stops, safety guards, and sensors for safe operation.

Budget: Balance upfront costs against long-term savings from efficiency and reduced labor.

Customizing Bale Size and Shape

Bale Dimensions: Length, width, and height can be adjusted to optimize storage or meet shipping container limits.

Bale Weight: Adjust compression force or cycle count to achieve target bale weights suitable for your transport or smelting requirements.

Shape: Square or rectangular bales stack more efficiently. Some balers produce bales with sharp corners for better stability.

Binding Method: Options include wire, steel straps, or plastic bands, depending on bale density and handling preferences.

Popular Models and Their Features

| Model Type | Bale Discharge Method | Compression Force | Suitable Materials | Automation Level | Notable Features |

| Side Turning Baler | Bale rotates 90° | High (up to 1000+ tons) | Steel, iron, heavy scrap | Semi-automatic to full | Produces dense bales with sharp corners |

| Forward Pushing Baler | Bale pushed forward | Medium | Aluminum, copper, cans | Manual to automatic | Simple design, ideal for lightweight scrap |

| Side Pushing Baler | Bale pushed sideways | Medium to high | Mixed metals | Semi-automatic | Saves labor, integrates with conveyors |

| Mobile Hydraulic Baler | Varies | Medium to high | Various metals | Automatic | Portable, suitable for on-site baling |

Maintenance and Troubleshooting of Hydraulic Scrap Metal Balers

Regular Maintenance Tips

Check Hydraulic Oil Levels: Always ensure the hydraulic oil tank is filled to the recommended level. Low oil can cause poor pressure and damage the system.

Replace Hydraulic Oil Periodically: Change oil as per the manufacturer’s schedule to avoid contamination and maintain fluid performance.

Lubricate Moving Parts: Bearings, hinges, and pistons need regular lubrication to reduce wear and keep operations smooth.

Inspect Seals and Hoses: Look for leaks or cracks in hydraulic hoses and seals. Replace damaged parts immediately to prevent failures.

Clean the Press Box: Remove metal scraps and debris after each use. This prevents blockages and ensures smooth bale formation.

Check Electrical Components: Regularly test safety switches, sensors, and control panels for proper function.

Tighten Bolts and Fasteners: Vibrations during operation can loosen bolts. Tighten them during routine checks to avoid mechanical problems.

Common Issues and Solutions

Hydraulic Pressure Drops: Often caused by low oil, leaks, or worn pump seals. Check oil levels and inspect hoses. Replace faulty seals or pumps.

Slow or Incomplete Compression: Could result from dirty oil, clogged filters, or worn cylinders. Change oil and filters, and inspect cylinders for damage.

Bale Jamming or Misalignment: Usually caused by debris in the press box or uneven loading. Clean the chamber and ensure scrap is loaded evenly.

Hydraulic Cylinder Leaks: Look for oil around cylinder rods. Replace worn seals or damaged cylinders promptly.

Electrical Failures: Faulty switches, wiring, or sensors can stop operation. Test electrical parts and repair or replace as needed.

Noise or Vibration: Excessive noise may indicate loose parts or worn bearings. Tighten components and replace worn parts.

Extending the Lifespan of Your Baler

Follow Manufacturer Guidelines: Stick to recommended maintenance schedules and operational limits.

Use Quality Hydraulic Oil: Good oil protects components and improves efficiency.

Train Operators: Proper operation reduces mechanical strain and accidents.

Perform Regular Inspections: Early detection of wear or damage prevents costly breakdowns.

Avoid Overloading: Do not exceed the baler’s capacity; overloads cause premature wear.

Store Properly: Protect the machine from harsh weather and corrosive environments.

By combining routine maintenance, timely repairs, and careful operation, you can keep your hydraulic scrap metal baler running efficiently for many years.

Future Trends in Hydraulic Scrap Metal Baling Technology

Innovations in Baling Press Technology

Hydraulic scrap metal balers continue to evolve with new technology improving efficiency and ease of use. One major innovation is the integration of intelligent electronic control systems. These systems monitor pressure, cycle times, and bale density in real-time, allowing automatic adjustments to optimize performance. Smart sensors help detect jams or abnormal pressure, reducing downtime and maintenance costs.

Another advancement is the use of wear-resistant materials in key components like press boxes and cylinders. These materials extend machine life and reduce repair frequency. Some balers now feature modular designs, making it easier to replace parts or upgrade systems without full machine replacement.

Energy-efficient hydraulic pumps and motors also reduce power consumption, lowering operational costs and environmental impact. Manufacturers are developing quieter balers that minimize noise pollution, improving workplace comfort and compliance with regulations.

Impact of Automation on the Industry

Automation is reshaping hydraulic scrap metal baling. Fully automatic balers can load, compress, bind, and discharge bales with minimal human intervention. This boosts productivity and cuts labor costs, especially in high-volume recycling centers.

Automation improves safety by limiting operator exposure to moving parts. Remote control and monitoring allow operators to oversee multiple machines from a safe distance. Data collected from automated balers supports predictive maintenance, helping identify issues before breakdowns occur.

Robotic arms and conveyors are increasingly integrated with balers to automate scrap feeding and bale stacking. This creates seamless workflows, reducing manual handling and speeding up processing times.

Predictions for the Next Decade

Looking ahead, hydraulic scrap metal balers will become smarter and more connected. The Internet of Things (IoT) will enable machines to communicate with recycling plant management systems, optimizing resource allocation and maintenance schedules.

Artificial intelligence (AI) may be used to analyze scrap types and adjust baling parameters dynamically for maximum density and quality. Energy recovery systems could capture and reuse heat generated by hydraulic components, further improving efficiency.

We expect balers to become more compact and mobile, allowing on-site baling at scrap collection points or demolition sites. This reduces transport needs and associated emissions.

Conclusion

Hydraulic scrap metal balers efficiently compress metal, reducing storage and transportation costs. They support sustainable recycling by minimizing waste and emissions. JSHH offers advanced balers with unique features, enhancing recycling operations with automation and safety. Investing in their products ensures efficient processing, cost savings, and environmental benefits.

FAQ

Q: How does a Hydraulic Scrap Metal Steel Copper Baling Press Bale work?

A: It uses hydraulic cylinders to compress metal in a press box, forming dense bales through sequential compression steps, then discharges the bale for recycling or transport.

Q: Why use a Hydraulic Scrap Metal Steel Copper Baling Press Bale?

A: It reduces storage and transport costs, improves recycling efficiency, and supports environmental sustainability by compacting scrap metal into dense bales.

Q: What are the benefits of a Hydraulic Scrap Metal Steel Copper Baling Press Bale?

A: Benefits include cost-effectiveness, space-saving, improved handling, reduced labor, and enhanced safety features for efficient metal recycling operations.