Introduction

What are scrap metal shears used for? These machines cut large metal pieces into smaller, manageable sizes.

In this article, we’ll explore the uses of scrap metal shears. You’ll learn how they improve recycling and boost efficiency, with insights into products like those from Huanhong.

What Are Scrap Metal Shears Used For?

Scrap metal shears are primarily designed to cut large, bulky metal pieces into smaller, uniform sizes. This enables easier handling, transportation, and processing of scrap metal. The ability to cut through various types of metal materials like steel, aluminum, and copper makes them versatile tools in the recycling and manufacturing sectors.

Key Industries that Rely on Scrap Metal Shears

Scrap metal shears are used in many industries where scrap metal needs to be processed efficiently. These industries include:

● Recycling: Scrap metal shears are an essential part of metal recycling operations, breaking down large scrap into manageable sizes.

● Construction: Scrap shears are used to cut steel beams, rebar, and other materials in demolition and construction projects.

● Manufacturing: Shears help reduce metal waste generated in manufacturing processes, making it easier to reuse materials.

● Automotive: In the automotive industry, scrap shears are used to dismantle vehicles and recycle metal parts like car frames.

Types of Metal Processed by Shears

Scrap metal shears can handle a wide variety of metals. The most common materials processed include:

● Steel: One of the most common metals used in construction and manufacturing, requiring powerful shear machines for processing.

● Aluminum: Lighter than steel, aluminum is easily processed by shears and is frequently recycled due to its demand in industries like aerospace and packaging.

● Copper: Known for its high value, copper scrap is often processed using specialized shears to recover high-quality material for reuse in electrical applications.

Scrap Metal Shears in the Recycling Industry

The Role of Scrap Metal Shears in Recycling Operations

Scrap metal shears are indispensable in recycling plants. They make scrap metal easier to manage by reducing it to uniform sizes. This allows the scrap to be transported, sorted, and processed more efficiently. Smaller, uniform pieces are also easier to smelt and recycle into new products, reducing the need for raw material extraction.

Enhancing Efficiency and Reducing Waste in Recycling

By cutting scrap metal into manageable pieces, scrap metal shears minimize the volume of waste. The process helps improve the recycling efficiency by creating uniform material sizes that can be handled more easily in subsequent processes, such as baling and smelting.

Improving the Quality of Recycled Materials

Using scrap metal shears ensures that the metal is cut into even pieces, enhancing its quality. The uniformity of the cuts ensures that the recycled metal is of high quality and can be used in manufacturing new products without contamination.

Tip: Investing in high-quality scrap shears improves the efficiency and profitability of your recycling operation by ensuring consistent material output and reducing waste.

Different Types of Scrap Metal Shears and Their Uses

Scrap metal shears come in various types, each designed for specific applications. The type of shear chosen depends on factors such as material size, volume, and the type of metal being processed.

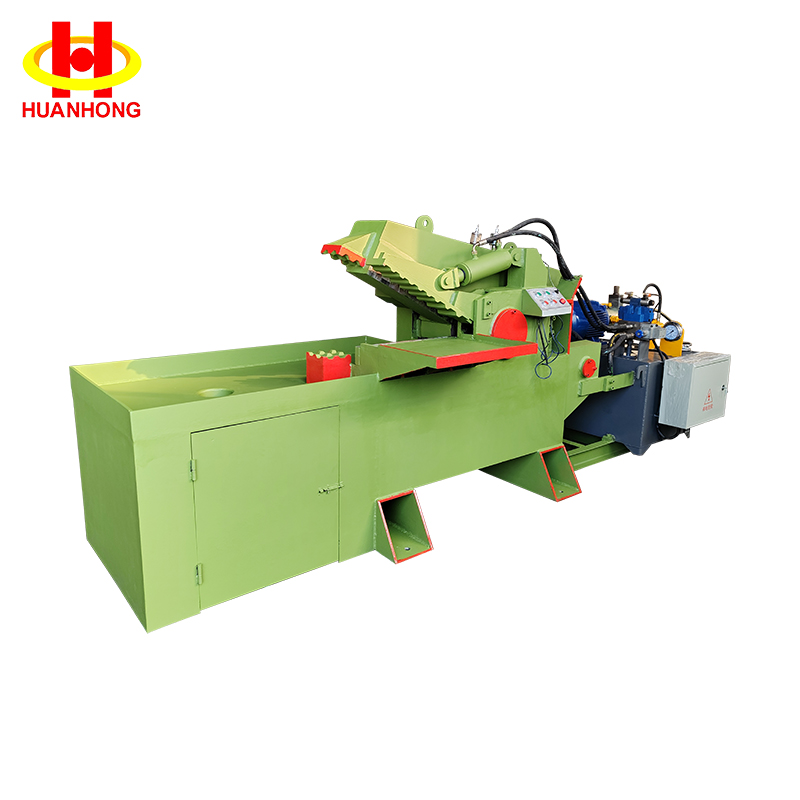

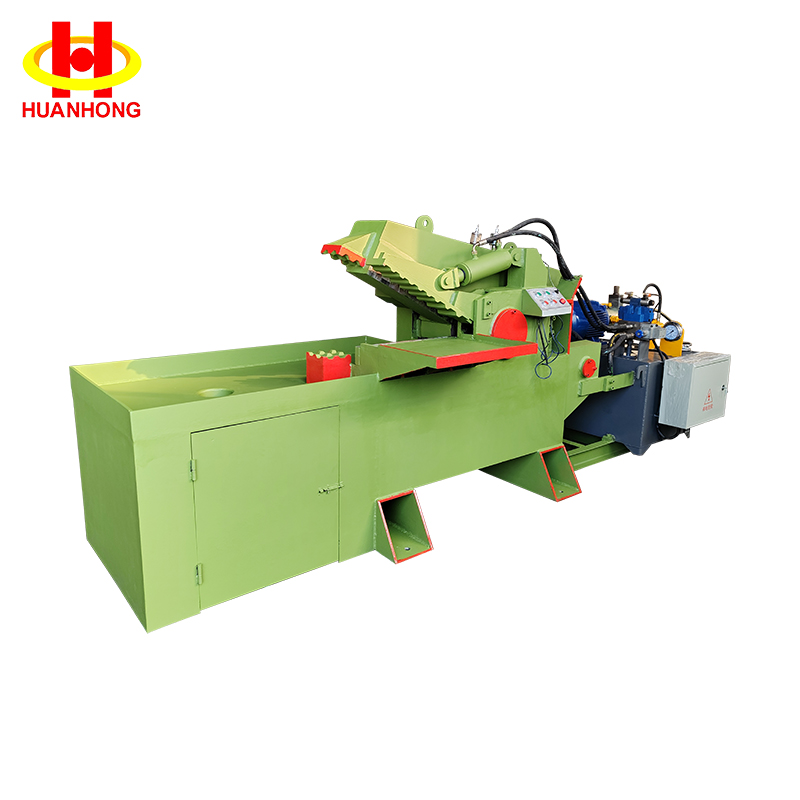

Alligator Shears

Alligator shears are designed with a jaw-like blade, making them ideal for cutting long pieces of scrap metal, such as rebar, pipes, and smaller components. These shears are highly portable and commonly used in smaller scrap yards and demolition sites.

Best for: Cutting long metal pieces, like rebar or pipes, in smaller operations.

Container Shears

Container shears are larger, fixed machines used for cutting thicker pieces of scrap metal, such as steel plates and structural beams. The vertical motion of the blade ensures precise and clean cuts, making them ideal for high-volume operations in scrap yards.

Best for: Cutting thick metal sheets and plates in high-volume operations.

Gantry Shears

Gantry shears are used for cutting large, heavy metals such as beams and pipes. These shears are usually fixed in place and operate on large volumes of scrap metal. They are ideal for large recycling plants that handle industrial-sized scrap.

Best for: High-volume scrap processing in large facilities.

Tip: Choose gantry shears for large operations where heavy-duty cutting is required, and precise cuts are essential.

Type of Shear | Best For | Advantages | Disadvantages |

Alligator Shears | Cutting long pieces of scrap like rebar or pipes | Portable, easy to operate in smaller sites | Limited to smaller, lighter scrap materials |

Container Shears | Cutting thick metal sheets and plates | High precision, ideal for high-volume cutting | Fixed machines, larger footprint |

Gantry Shears | Heavy-duty scrap metal like beams or pipes | Handles large volumes of scrap metal | Requires large space, costly |

How Scrap Metal Shears Improve Efficiency and Reduce Costs

Faster Processing of Scrap Metal

Scrap metal shears increase processing speed significantly. With automated and hydraulic-powered systems, scrap metal can be cut quickly and consistently, reducing the time spent on manual cutting methods. This faster processing leads to higher throughput, enabling recycling facilities to handle more scrap in less time.

Reducing Transportation Costs Through Size Reduction

One of the key benefits of using scrap metal shears is the reduction in scrap volume. When large metal pieces are cut into smaller, uniform sizes, they take up less space. This makes it easier and more cost-effective to transport the scrap, leading to lower transportation costs. Smaller loads are easier to pack into containers, which maximizes space and reduces fuel consumption.

Minimizing Waste and Increasing Material Recovery

Scrap shears help reduce material waste by producing clean, precise cuts. This process ensures that as much metal as possible is recovered and reused. The smaller, denser pieces are easier to store, transport, and process, allowing recycling operations to recover a greater amount of material and reduce their environmental impact.

The Benefits of Using Scrap Metal Shears in Construction and Demolition

Dismantling Metal Structures

Scrap metal shears are often used in construction and demolition projects to dismantle metal structures like beams, rebar, and pipes. These shears help break down large metal components, making them easier to transport to recycling facilities.

Reducing the Risk of Injury in Demolition

Using scrap shears reduces the need for manual cutting, which lowers the risk of injury. Unlike manual cutting tools, shears require less physical effort and are safer to use in demolition environments. This enhances safety standards and minimizes workplace accidents.

Benefit | Impact | Example |

Faster Processing | Increases throughput, cuts metal quickly | Automated systems allow for rapid cutting, improving efficiency |

Reduced Waste | More precise cuts, less material loss | Scrap shears reduce unnecessary waste, improving recycling efficiency |

Lower Transportation Costs | Smaller scrap takes up less space and is cheaper to transport | Smaller, uniform pieces allow for more efficient packing and shipping |

Scrap Metal Shears in the Steel Industry

Cutting Scrap Steel for Efficient Smelting

In the steel industry, scrap metal shears are used to cut scrap steel into smaller pieces, making it easier to transport and melt. By cutting scrap steel into uniform sizes, shears improve the efficiency of the melting process and reduce the energy required to melt down the metal.

Enhancing Steel Recycling and Reducing Costs

Scrap metal shears in the steel industry help reduce operational costs by making the recycling process more efficient. Smaller pieces of scrap steel allow for better material handling and reduced waste, making the recycling process faster and more cost-effective. The use of shears also ensures higher-quality steel output in the recycling process, reducing the need for new raw materials.

Shear Type | Used For | Advantages | Disadvantages |

Gantry Shears | Heavy scrap steel processing | High capacity, efficient for large volumes | Expensive, requires large space |

Container Shears | Cutting steel for smelting | Precise, can handle various steel types | Slower for smaller operations |

Alligator Shears | Cutting scrap steel for easy transportation | Portable, quick, good for on-site cutting | Limited capacity for larger scrap sizes |

The Environmental Benefits of Using Scrap Metal Shears

Promoting Sustainable Practices in Recycling

Scrap metal shears play a vital role in promoting sustainability in recycling operations. By cutting scrap into smaller pieces, they increase the efficiency of metal recovery and reduce the amount of metal that ends up in landfills. This contributes to a circular economy where materials are reused and recycled, reducing the environmental footprint of industrial activities.

Lowering Carbon Footprint in Recycling Operations

Efficient scrap metal shearing reduces energy consumption by minimizing waste and making the recycling process quicker and less resource-intensive. As a result, businesses can reduce their overall carbon footprint, contributing to environmental preservation while maintaining operational efficiency.

Conclusion

Scrap metal shears are vital tools in recycling, construction, and demolition industries. They improve efficiency by cutting scrap metal into smaller, manageable pieces, making recycling easier and more cost-effective. These machines help reduce waste and enhance sustainability. Companies like Huanhong offer high-performance scrap shears that optimize recycling operations, ensuring value and reliability across industries.

Tip: Choosing the right scrap shear for your operation increases overall efficiency and profitability, making it a valuable investment for businesses in recycling and demolition.

FAQ

Q: What is a scrap metal shear used for?

A: A scrap metal shear is used to cut large metal objects into smaller, manageable pieces for recycling or processing.

Q: How do scrap metal shears improve recycling efficiency?

A: Scrap metal shears enhance recycling by quickly reducing scrap into uniform sizes, improving sorting, storage, and transportation.

Q: What types of metals can be processed with scrap metal shears?

A: Scrap metal shears can handle various metals such as steel, aluminum, copper, and more, depending on shear capacity.

Q: Why should I invest in high-quality scrap metal shears?

A: High-quality shears, like those from Huanhong, offer better durability, reduce maintenance, and improve operational efficiency.