Introduction

What are the different types of Gantry shears? These machines cut large metal pieces into smaller sections.

In this article, we’ll explore the various Gantry shears and their uses. You’ll learn how they improve efficiency in industries like recycling and steel production. Products from Huanhong optimize cutting operations.

Understanding Gantry Shears

What is a Gantry Shear?

A Gantry shear is a large, stationary cutting machine that is primarily used to cut scrap metal into smaller, more manageable pieces. The machine uses a vertical blade that moves up and down, applying force to shear through thick metal. Gantry shears are built for heavy-duty cutting, making them ideal for industries such as scrap metal recycling, steel mills, and demolition.

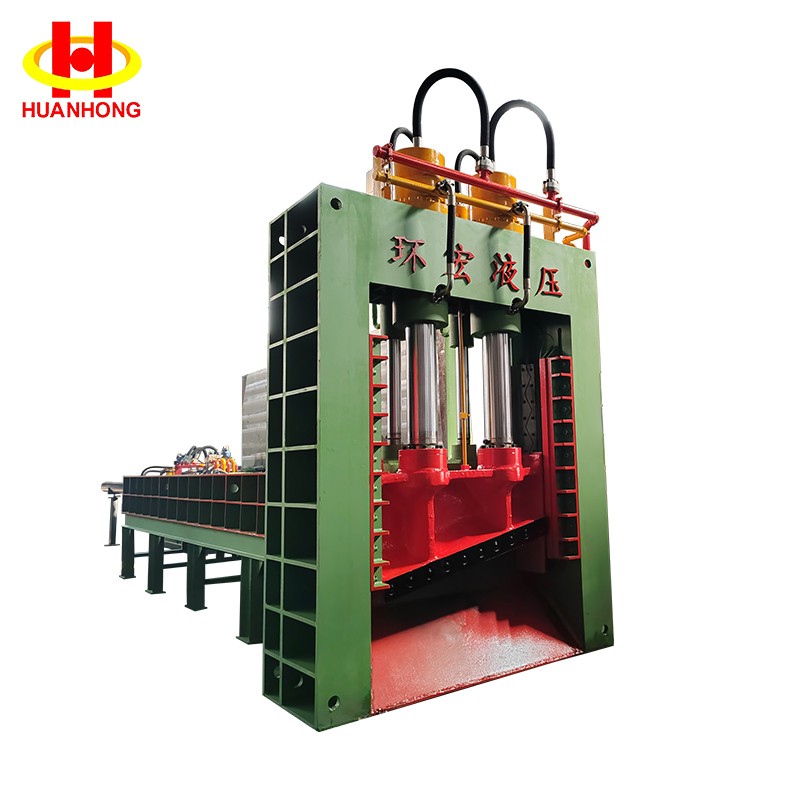

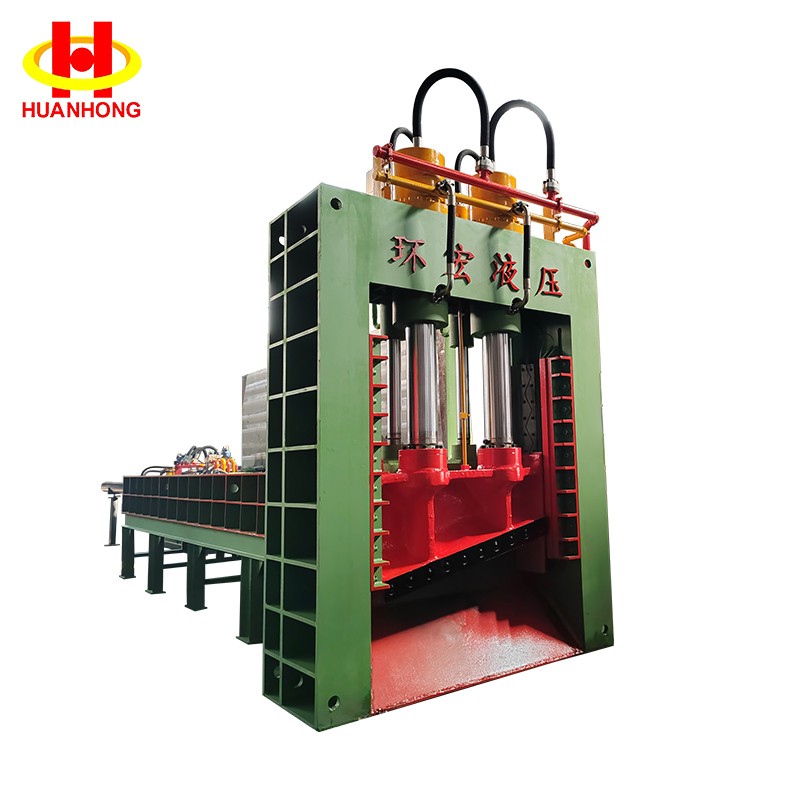

Hydraulic Gantry shears are among the most commonly used types in large-scale operations. With their powerful cutting force and versatile design, they are capable of processing a wide range of metals, such as steel, aluminum, copper, and iron. These machines are essential in reducing large, bulky pieces of scrap metal into smaller, uniform sections, streamlining recycling and reprocessing. For instance, hydraulic Gantry shears efficiently process steel beams, copper plates, or rebar in scrap metal yards, ensuring quicker and safer handling of materials.

Key Features of Gantry Shears

Gantry shears are typically equipped with hydraulic systems that deliver high cutting force while maintaining stability throughout the cutting process. This hydraulic mechanism allows them to easily shear through large, dense metal pieces, making them highly effective for industrial-scale operations. Additionally, these shears operate at high speeds, improving overall efficiency and productivity in metal processing.

Several important features enhance the performance of Gantry shears:

● Stable Hydraulic Operation: The hydraulic system operates with minimal noise and vibration, offering consistent and stable performance during high-load tasks. This reliability is essential for maintaining efficiency in various industrial applications.

● Durability: Built with wear-resistant alloy steel plates, Gantry shears are designed for longevity and high durability, making them resistant to the demands of continuous, heavy-duty use.

● High Shearing Efficiency: Gantry shears are known for their high throughput, capable of achieving cutting speeds of 3–4 cuts per minute. This increases productivity, especially in high-volume recycling operations.

Common Uses of Gantry Shears

Gantry shears are indispensable tools in various industries. Their robust design and cutting efficiency make them suitable for a wide range of applications, including:

● Scrap Metal Recycling: Gantry shears are widely used in scrap metal yards to cut large scrap metal pieces into smaller, more manageable sections. This process facilitates easier recycling, storage, and transportation of scrap metal, ensuring that valuable materials are reused effectively.

● Construction and Demolition: In demolition projects, Gantry shears are essential for cutting through steel beams, rebar, and other structural metals. These shears enable faster and more efficient dismantling of buildings and structures, helping to reduce manual labor and minimize downtime in demolition sites.

● Steel Production: In steel mills, Gantry shears play a critical role in preparing scrap metal for melting. By cutting down large scrap pieces into smaller, uniform sections, they make it easier to load and process the material for reuse in steel production. This enhances the efficiency of the melting process and helps optimize resource use.

Types of Gantry Shears

There are several types of Gantry shears, each designed for specific applications and cutting requirements. The three main types of Gantry shears are:

Hydraulic Gantry Shears

Hydraulic Gantry shears are designed for heavy-duty cutting and are widely used in scrap metal recycling and steel mills. These shears use hydraulic power to generate immense cutting force, enabling them to handle the toughest metals. Hydraulic Gantry shears are typically capable of processing large scrap metal pieces, including steel beams, iron plates, and aluminum sheets. This type of shear is ideal for industries that require high power and precision when cutting large materials.

Advantages:

● High cutting force suitable for large and heavy metals

● Versatile and can handle various materials

● Efficient and durable with high throughput

Disadvantages:

● Expensive initial investment

● Requires a large installation space, which may not be ideal for smaller facilities

Mobile Gantry Shears

Mobile Gantry shears offer flexibility and mobility. These machines are mounted on tracks or wheels, allowing them to be moved to different locations for scrap processing. Mobile Gantry shears are particularly useful for on-site cutting in construction, demolition, and scrap processing projects where mobility is essential. The ability to move these machines to various work locations makes them versatile in a variety of applications.

Advantages:

● Can be moved to various locations for on-site cutting

● Ideal for construction sites and demolition projects that require flexible equipment

Disadvantages:

● Lower cutting capacity compared to stationary models

● Not suitable for large-scale processing or heavy-duty cutting tasks

Gantry-Type Guillotine Shears

Gantry-type Guillotine shears feature a large vertical blade that moves down to cut metal sheets, bars, and other metal materials. These shears are known for their high precision and are often used in industries that require clean, accurate cuts for metal plates and profiles. They are commonly employed in manufacturing and metal fabrication, where cutting precision is critical. These shears are well-suited for tasks that require fast, accurate cuts in lighter metals.

Advantages:

● High precision and accuracy for clean cuts

● Ideal for cutting thin and medium-gauge metal sheets and profiles

Disadvantages:

● Limited to smaller scrap pieces or thinner materials

● Requires fixed installation with enough floor space, limiting mobility compared to other shear types

Shear Type | Cutting Capacity | Best Use | Advantages | Disadvantages |

Hydraulic Gantry Shears | High cutting capacity for large metals | Scrap metal recycling, steel mills | High power, versatile, efficient | Expensive, requires large space |

Mobile Gantry Shears | Limited cutting capacity | On-site cutting for demolition, flexible operations | Portable, flexible for job sites | Lower cutting force, limited for large scrap |

Gantry-Type Guillotine | Precision for cutting metal sheets | Cutting metal plates, bars, and profiles | High precision, clean cuts | Limited to smaller materials, fixed installation needed |

Key Applications of Gantry Shears

Scrap Metal Recycling

Gantry shears are indispensable in the recycling industry. They reduce large metal objects like steel beams, vehicle frames, and construction debris into smaller, more manageable pieces. This process is crucial for efficiently sorting and processing materials for recycling. The versatility of hydraulic Gantry shears allows them to handle a wide range of materials, from heavy-duty steel to lighter metals like aluminum.

Steel Mill Operations

In steel mills, Gantry shears are used to process scrap steel before it is melted down and reused in steel production. By cutting large scrap metal into smaller, uniform pieces, Gantry shears ensure that the material can be efficiently fed into the furnace, optimizing the melting process and reducing energy consumption.

Construction and Demolition

Gantry shears play a vital role in demolition projects, where they are used to cut through metal beams, rebar, and other structural materials. This makes it easier to dismantle buildings and structures for recycling or reuse. These shears significantly improve efficiency in demolition operations, reducing the need for manual labor.

Comparing Gantry Shear Types

Hydraulic vs. Mechanical Gantry Shears

Feature | Hydraulic Gantry Shears | Mechanical Gantry Shears |

Cutting Capacity | Higher, capable of cutting large scrap metals | Lower cutting capacity compared to hydraulic models |

Speed | Slower due to powerful hydraulic systems | Faster, suitable for quicker cuts |

Maintenance | Requires more maintenance due to hydraulic systems | Generally simpler to maintain |

Cost | Expensive initial investment | More affordable upfront cost |

Mobile Gantry Shears vs. Fixed Gantry Shears

Feature | Mobile Gantry Shears | Fixed Gantry Shears |

Portability | Can be moved to different locations | Stationary, fixed installation |

Cutting Capacity | Limited cutting capacity | Higher cutting capacity for large materials |

Ideal Use | On-site operations and demolition projects | High-volume scrap metal processing |

Advantages of Gantry Shears in Heavy-Duty Operations

Enhanced Cutting Precision

Gantry shears provide high precision, ensuring metal materials are cut into uniform sizes. This level of accuracy is particularly important in industries that require clean, precise cuts, such as steel production, scrap metal recycling, and automotive manufacturing. The shear's ability to make clean, straight cuts helps improve the quality of the final product and makes downstream processing more efficient.

Increased Operational Efficiency

By automating the cutting process, Gantry shears significantly reduce labor costs and improve processing speed. They are capable of handling large volumes of scrap metal quickly, making them ideal for operations that need to process heavy materials in high quantities. Gantry shears also reduce the manual effort required, allowing workers to focus on other essential tasks while the machine handles the cutting efficiently.

Durability and Maintenance Benefits

Gantry shears are designed to withstand the heavy demands of industrial operations. Built with robust materials and components, these machines are well-suited for long-term use. When properly maintained, Gantry shears can last for many years, offering consistent performance. Their durable construction minimizes the need for frequent repairs, contributing to lower maintenance costs and less downtime in operations.

Selecting the Right Gantry Shear for Your Needs

Capacity and Force Requirements

When selecting a Gantry shear, it's essential to consider the cutting capacity and force required for the materials you are processing. Gantry shears vary in terms of cutting force, with models designed to handle everything from smaller, lighter metals to large, thick scrap materials. High-capacity shears are necessary for industries that process heavy metals like steel, while lighter models can handle smaller materials, ensuring efficient cutting and reducing energy consumption.

Material Type and Thickness

Choosing the right Gantry shear depends on the material type and thickness of the metal being cut. Lighter metals, such as aluminum, require less cutting force compared to denser materials like steel or iron. It's essential to select a shear that can provide the necessary force to cut through the materials effectively. Shears with adjustable settings can offer versatility, allowing operators to handle a variety of materials with different thicknesses.

Space and Operational Flexibility

The available space in your facility should be considered when selecting a Gantry shear. If space is limited, mobile Gantry shears are an excellent option, providing flexibility for on-site cutting or movement between different areas. On the other hand, if your operation requires high-volume processing in a fixed location, larger, stationary Gantry shears are ideal. The choice depends on your operational needs and the size of your workspace.

Conclusion

Gantry shears are powerful tools that play a significant role in industries such as metal recycling, steel production, and demolition. Understanding the different types of Gantry shears and their applications is crucial for selecting the right machine for your operation. Companies like Huanhong provide high-performance Gantry shears that meet industry standards and provide exceptional value across various applications.

Tip: Consider your facility’s space, the type of metal you process, and the required cutting force when choosing the right Gantry shear for your needs.

FAQ

Q: What are the different types of Gantry shears?

A: Gantry shears come in hydraulic, mobile, and guillotine types. Each is suited for different cutting needs, from heavy-duty operations to portable, on-site cutting.

Q: How do hydraulic Gantry shears work?

A: Hydraulic Gantry shears use hydraulic pressure to generate high cutting forces, making them ideal for heavy-duty scrap metal processing and high-volume operations.

Q: Why choose a mobile Gantry shear?

A: Mobile Gantry shears are portable and flexible, perfect for on-site cutting in demolition and recycling projects, providing mobility and ease of use.

Q: What are the advantages of Gantry-type Guillotine shears?

A: Gantry-type Guillotine shears offer precise cuts, making them ideal for cutting metal sheets and profiles with high accuracy in manufacturing applications.