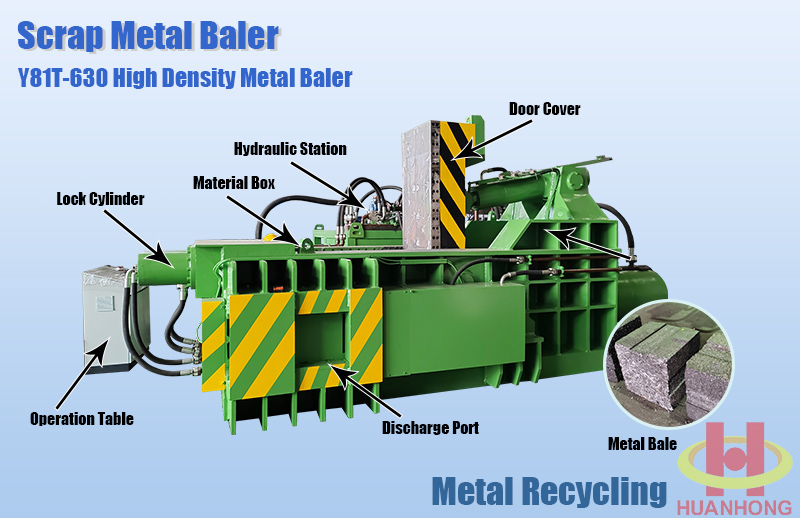

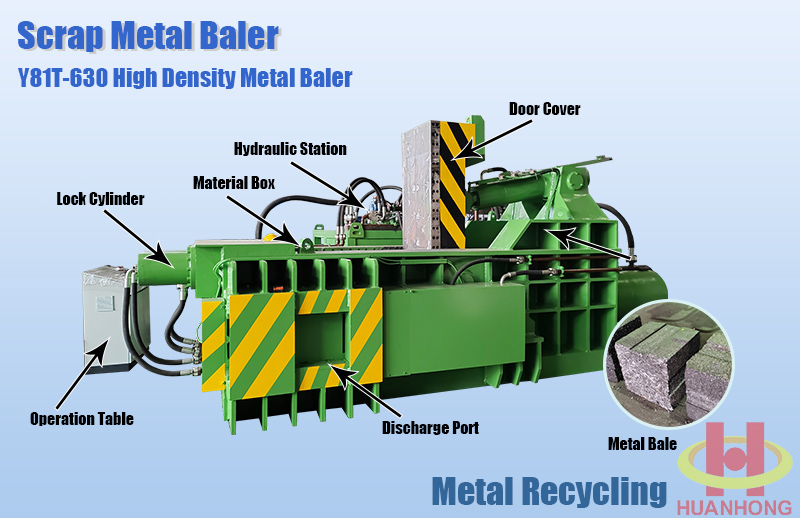

Introduction of the high density metal baler

This is a high-pressure and high-density hydraulic metal baler. Compared with balers of the same pressure, this 630-ton metal baler has a smaller material box, which is 1200*800*800mm in size, and the cross-sectional size of the processed metal bales is 300*300mm. The metal bales pressed out by this high-pressure and high-density metal baler are denser and more compact. Our Y81 series hydraulic metal balers are all hydraulically driven, which can compress various scrap metal materials into regular rectangular blocks, which is convenient for storage and transportation, and greatly saves labor costs. Our metal balers have a dozen levels of baling pressure ranging from 125 tons to 4000 tons. You can choose the appropriate model according to customer needs. At the same time, the material box size and bale size of the equipment can be customized.

Technical specification of the high density metal baler

Technical specification of Y81T630 metal baler |

Model | Y81T-630 |

Nominal pressure(kn) | 6300 |

Press box size(L*W*H)(mm) | 1200*800*800 |

Bale size(W*H)(mm) | 300*300 |

Power(kw) | 148 |

The above parameters are for reference only. The balers can be customized.

Features of the high density metal baler

1. All metal balers are hydraulically driven and have a powerful pressure system. The equipment can be controlled by manual valve or PLC automatically, which is simple and convenient to operate.

2. Metal balers have a variety of discharging methods, including flip-out, push-out and manual grabbing. This high-density metal baler adopts the side-push type.

3. Metal balers are easy to install and do not require anchor screws.

4. Metal balers can be powered by diesel generators in places without electricity.

Applications of the high density metal baler

For metal processing companies, hydraulic metal balers are an ideal choice for processing production scraps. It can quickly compress the metal scraps generated during the production process into blocks, which not only saves storage space, but also improves the cleanliness and work efficiency of the production site. In the steel smelting industry, hydraulic metal balers pre-process scrap steel into high-density blocks, making it easier to put into steelmaking furnaces, improving steelmaking efficiency and reducing energy consumption, while optimizing the quality of furnace charges and reducing impurities. In addition, hydraulic metal balers perform well in the fields of logistics and warehousing. It can compress scrap metal into smaller and denser blocks, greatly reducing transportation costs while optimizing storage space utilization. In the field of environmental protection and resource recycling, hydraulic metal balers convert scrap metal into reusable resources through efficient compression and packaging, reducing resource waste, reducing environmental pollution, and helping companies achieve sustainable development goals.

Other Balers Recommended