Introduction

Ever wondered how scrap gantry shears work? These powerful machines cut large metal scraps into manageable pieces.

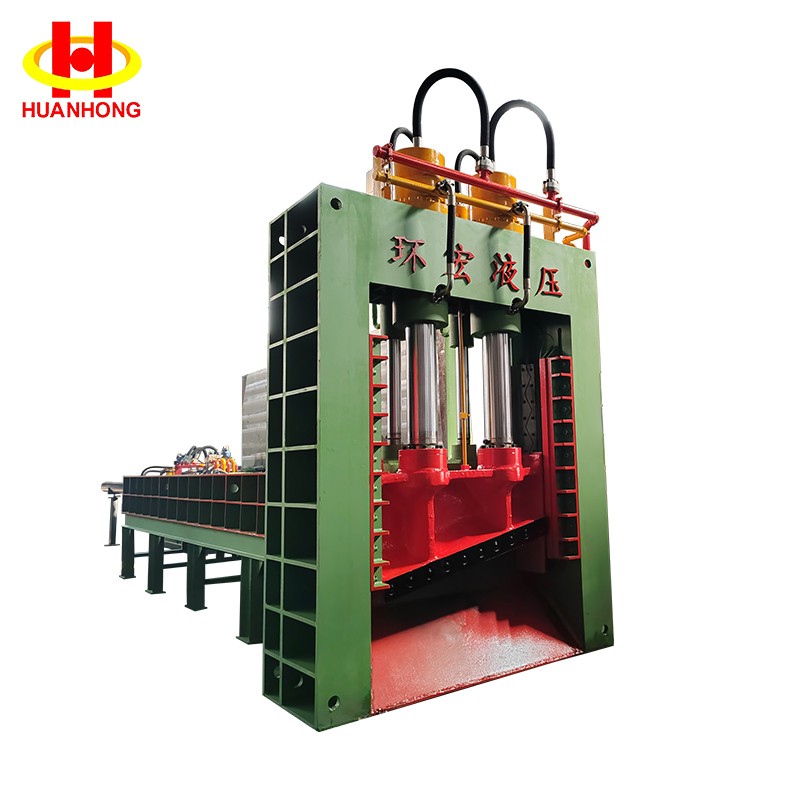

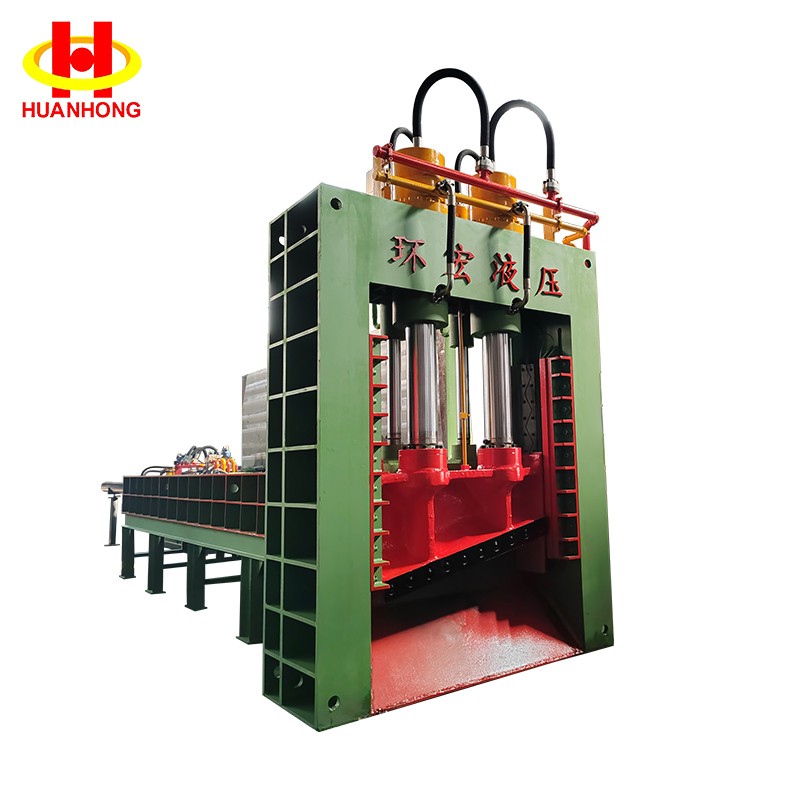

In this article, we’ll explore the principle behind scrap gantry shears. You’ll learn how they operate, their key components, and how they’re used in industries like recycling and steel production. Products from Huanhong improve cutting efficiency and precision.

Overview of Gantry Shears and Their Role

What Are Gantry Shears?

Gantry shears are large, hydraulic-powered machines designed for cutting scrap metal into smaller pieces. The "gantry" structure refers to the frame that supports the shear blades, which move with immense power to cut through heavy materials. These shears are commonly used in industries that process large quantities of scrap metal, such as scrap yards, steel mills, and construction sites.

One of the key factors in their functionality is the shear's ability to handle different types of metals. Whether it's steel, aluminum, or copper, these machines are engineered to slice through various materials with precision and efficiency. Gantry shears are also commonly used to break down metal pieces into manageable sections for further recycling and reuse, ensuring that scrap metal is not only processed effectively but also efficiently.

Key Features and Functionality

Gantry shears are powered by hydraulic systems, which generate the cutting force required to shear through heavy metal pieces. The machines feature high-strength, durable blades and a robust gantry frame that supports the entire cutting operation. This ensures that even the toughest materials can be cut accurately and without compromising machine performance. Gantry shears can be equipped with multiple cutting blades and adjustable settings, offering versatility in processing different metal types and thicknesses.

Moreover, these machines can be optimized for specific tasks. For instance, some Gantry shears can be set up for fast cutting cycles, capable of achieving up to 3–4 cuts per minute, depending on the model and the material being processed.

How Gantry Shears Are Used in Industry

Gantry shears are used in various industrial settings, such as:

● Scrap Metal Recycling: These shears help reduce scrap metal into smaller pieces, making them easier to handle and transport.

● Construction and Demolition: They are used to cut through large metal beams and rebar during demolition or renovation projects.

● Steel Production: In steel mills, Gantry shears are used to cut scrap metal into pieces suitable for melting and processing in furnaces.

The Basic Principle Behind Gantry Shear Operation

Hydraulic Power and Force Generation

The core principle of Gantry shears lies in the hydraulic power system. Hydraulic cylinders, powered by high-pressure oil, generate the immense force required to cut through tough metal. The hydraulic system drives the shearing action, ensuring the blade moves with enough force to slice through large scrap metal pieces quickly and effectively.

The hydraulic power allows Gantry shears to handle materials with a thickness and density that would otherwise be impossible to process with conventional cutting tools. The efficiency of the system also ensures minimal energy loss and maximum output.

The Role of the Gantry Frame

The gantry frame serves as the structural backbone of the shear. It supports the entire cutting mechanism, including the hydraulic system, the blade, and other essential components. This framework must be robust and stable enough to handle the high forces generated during cutting. The frame’s design also ensures that the cutting operation remains stable, allowing for precise cuts and maintaining the shear's performance over long periods of use.

The gantry frame’s rigidity also reduces the chances of errors or misalignment during operation, ensuring that the cut pieces are uniform and meet the required specifications for further processing or recycling.

The Shearing Process

The shearing process involves a sharp cutting blade, which moves vertically under hydraulic power. When the scrap metal is placed in the cutting area, hydraulic clamps hold it firmly in place to prevent shifting during the cutting process. The upper blade then moves downward with significant force, slicing through the metal until the required size is achieved. Afterward, the cut pieces are ejected for sorting or recycling.

The precision and force with which the blade cuts make Gantry shears ideal for processing a wide range of materials, from light metals like aluminum to heavy-duty scrap like steel beams.

Core Components of a Gantry Shear

The Hydraulic System

The hydraulic system is the heart of the Gantry shear. It consists of pumps, hydraulic cylinders, and reservoirs that work together to generate the force required for cutting. The hydraulic system’s performance is critical to the shear’s overall functionality and efficiency. Regular maintenance and monitoring are necessary to ensure smooth operation and to avoid system failures.

The Shear Blade

The shear blade is typically made of high-strength steel or wear-resistant materials. This blade needs to withstand repeated, high-impact cutting cycles without dulling or breaking. As the blade contacts the scrap metal, it must maintain its sharpness and integrity to perform precise cuts. Over time, the blade may require sharpening or replacement to ensure continued cutting accuracy.

The Gantry Frame

The gantry frame provides structural support for all components of the shear. It ensures that the hydraulic power and shear blade are aligned properly, maintaining stability throughout the operation. The frame is usually built from reinforced materials to withstand the high stresses generated by the cutting process.

Component | Function | Key Benefits | Considerations |

Hydraulic System | Powers the shear blade with high cutting force | Provides immense cutting force, precision | Requires regular maintenance for optimal performance |

Shear Blade | The cutting edge that shears through scrap metal | Durable, precise cuts | Needs to be replaced or sharpened over time |

Gantry Frame | Provides structural support for all components | Ensures stability and precision | Must be robust enough to handle high forces |

The Cutting Cycle in Gantry Shears

Loading and Feeding

Before the cutting cycle begins, scrap metal is fed into the machine’s cutting area. This is typically done using a conveyor or feeding hopper, where the material is placed in the optimal position for cutting.

Clamping and Holding the Material

Once the metal is positioned, hydraulic clamps secure the scrap in place to prevent movement during the cutting process. This ensures that the shear blade cuts through the material evenly and accurately.

Shearing Action and Discharge

The upper blade moves downwards under the applied hydraulic force, cutting through the metal. After the cutting is complete, the material is ejected from the cutting area and prepared for further processing or recycling.

Automation for Continuous Operation

Many modern Gantry shears are automated to streamline the process, reduce human labor, and increase productivity. Automated systems control the feeding, clamping, and cutting cycles, allowing for continuous operation without interruptions.

Step | Description | Importance |

Loading and Feeding | Scrap metal is positioned in the cutting area | Ensures proper alignment for efficient cutting |

Clamping and Holding | Hydraulic clamps secure the material | Prevents movement during cutting, ensuring clean cuts |

Shearing Action | The upper blade moves downward to cut the metal | The core action for separating metal into manageable pieces |

Discharge | The cut metal is ejected for further processing | Helps in smooth handling and storage of processed material |

Efficiency and Speed of Gantry Shears

Cutting Force and Speed

Gantry shears are designed to cut large volumes of scrap metal quickly. Their hydraulic systems generate substantial cutting force, enabling fast and efficient processing of various metal types. The machines can cut multiple pieces of scrap metal per minute, which significantly improves the efficiency of industrial operations.

Continuous Operation

Due to their robust design, Gantry shears can operate continuously for extended periods, making them ideal for high-volume operations in recycling and steel mills. Continuous operation leads to higher productivity, reduced downtime, and more cost-effective metal processing.

Customization for Specific Tasks

Gantry shears are versatile and can be customized for specific tasks. Adjustments to cutting force, speed, and other settings allow operators to handle different materials and metal thicknesses with ease, ensuring optimal results.

Safety Measures and Operational Considerations

Hydraulic Safety Mechanisms

Safety is a priority in Gantry shear operations. The hydraulic system is equipped with safety features like pressure relief valves to prevent overloading and avoid system malfunctions.

Operator Protection

Operator safety is ensured with safety guards, automatic shutoff systems, and emergency stop features. These measures reduce the risk of accidents and injuries during operation.

Maintenance for Safe Operations

Regular maintenance is essential to keeping Gantry shears running safely and efficiently. Inspection of the hydraulic system, shear blades, and other components is necessary to prevent accidents and extend the lifespan of the machine.

Applications of Gantry Shears in Industry

Metal Recycling

Gantry shears are commonly used in scrap metal recycling to break down large pieces of scrap metal into smaller, more manageable sections, making the materials easier to sort and recycle.

Steel Mill Operations

In steel mills, Gantry shears are used to cut scrap steel into suitable sizes for melting in furnaces. This improves efficiency and reduces the need for raw materials.

Demolition and Construction

In demolition and construction, Gantry shears are essential for cutting large metal structures. They enable quick dismantling of metal components, making it easier to recycle the materials.

Industry | Primary Use | Benefits |

Metal Recycling | Cuts scrap metal into smaller pieces for recycling | Increases efficiency, reduces labor, and enhances material recovery |

Steel Mills | Prepares scrap steel for melting in furnaces | Improves efficiency in steel production by reducing raw material use |

Demolition and Construction | Cuts metal structures during demolition | Speeds up the demolition process and enables recycling of metal parts |

Conclusion

The principle of scrap gantry shears relies on hydraulic power, which generates the force needed to cut large metal pieces into smaller sections. These machines play a crucial role in industries such as recycling, steel production, and construction. Understanding how they work allows businesses to optimize operations for better productivity and safety. Regular maintenance and proper selection of shear models ensure peak performance. Products from Huanhong enhance efficiency, providing excellent value across various industries.

FAQ

Q: What is the principle behind scrap gantry shears?

A: The principle of scrap gantry shears is based on hydraulic power. This generates immense force, enabling the shears to efficiently cut large metal pieces into smaller sections for recycling or processing.

Q: How do scrap gantry shears work?

A: Scrap gantry shears use hydraulic cylinders to apply significant force on a cutting blade, which moves to shear scrap metal into manageable sizes.

Q: Why are hydraulic gantry shears preferred for heavy-duty operations?

A: Hydraulic gantry shears provide the necessary cutting power for large, dense materials, offering greater force and precision compared to mechanical shears.

Q: How does regular maintenance affect the performance of gantry shears?

A: Regular maintenance ensures that the hydraulic system and blades function optimally, prolonging the shear's lifespan and maintaining cutting efficiency.