Introduction

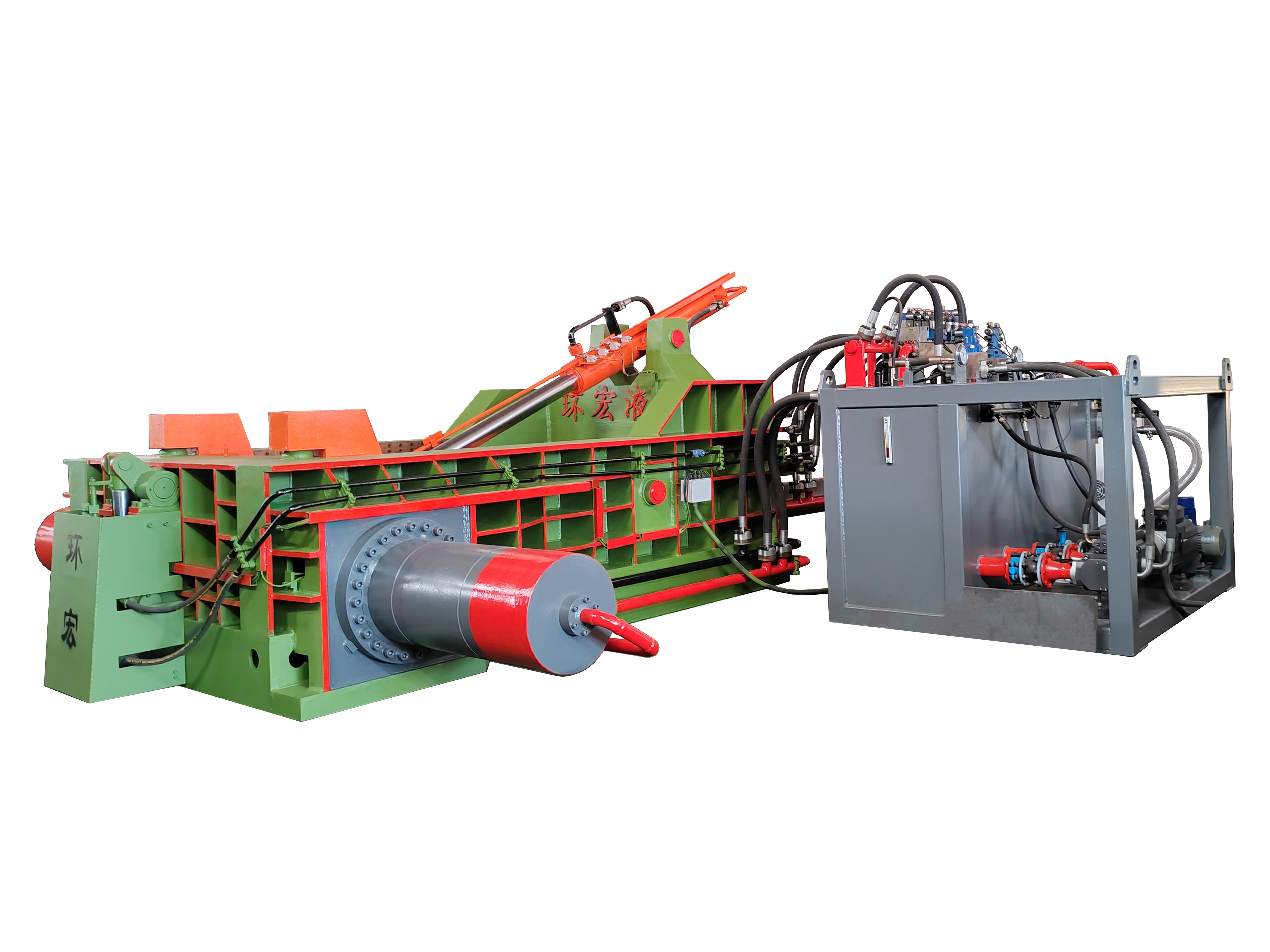

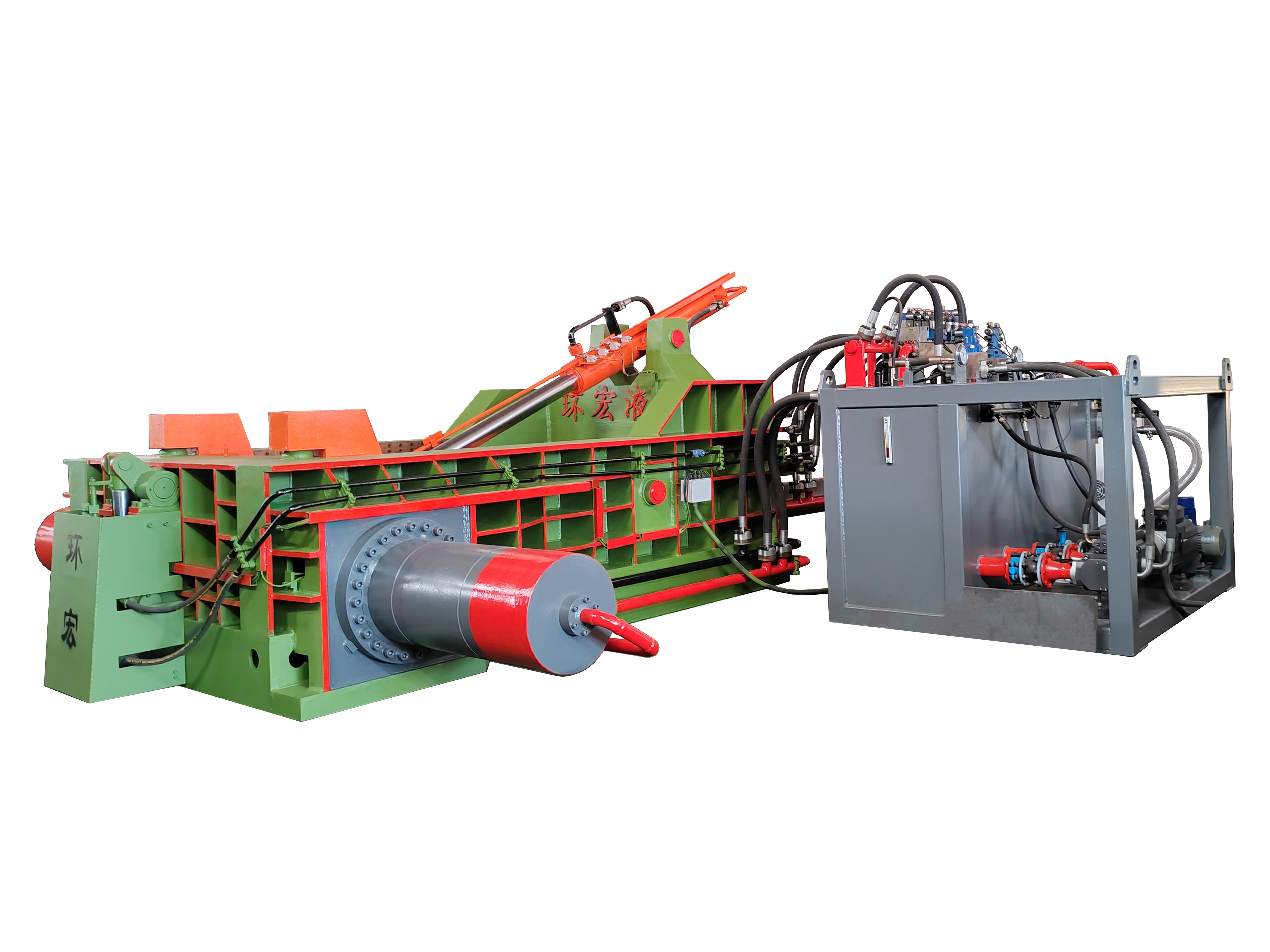

Imagine transforming heaps of scrap metal into compact, manageable bales with ease. That's the magic of a Hydraulic Scrap Metal Steel Copper Baling Press Bale. These machines are vital in the recycling industry, efficiently compressing metals like steel and copper. In this article, you'll learn about their key features, benefits, and how they revolutionize recycling processes.

Understanding the Hydraulic Scrap Metal Baling Process

How Does Hydraulic Pressure Work?

Hydraulic scrap metal baling presses use hydraulic pressure to compact scrap metal into dense bales. The system relies on a hydraulic pump that pushes fluid through cylinders. This fluid pressure moves pistons inside the cylinders, generating a strong compressive force. The force presses the scrap tightly into a compact shape. This method allows for consistent, powerful compression that manual or mechanical presses can't match.

The hydraulic system typically includes a reservoir for hydraulic fluid, a pump to pressurize the fluid, valves to control flow, and cylinders that convert pressure into mechanical force. The smooth operation of these parts ensures the baler can compress large volumes of scrap efficiently and safely.

Steps in the Baling Process

Loading: Scrap metal is loaded into the baler’s compression chamber. This can be done manually or via conveyor belts for larger operations.

Pre-Compression: The upper cover or door closes to contain the scrap securely. Initial compression may start here to prepare the material.

Compression: Hydraulic cylinders apply pressure from multiple angles — typically from the top, sides, and sometimes the door cover. This multi-directional compression ensures a uniform, dense bale.

Holding Pressure: The system maintains pressure for several seconds to ensure the bale retains its shape and density.

Ejection: After compression, the bale is ejected using hydraulic cylinders. Common ejection methods include side push, front push, or bale flipping.

Cycle Repeat: The machine resets for the next batch.

Efficiency and Productivity Enhancements

High Compression Force: The hydraulic system can generate pressures from 125 to 400 tons or more, allowing it to compact heavy metals like steel and copper into dense bales.

Automated Controls: Many balers use programmable logic controllers (PLCs) for automatic operation. This reduces manual labor and increases throughput.

Multi-Cylinder Design: Using main, side, and upper cylinders simultaneously compresses scrap from multiple directions, ensuring consistent bale density.

Fast Cycle Times: Modern balers complete a full compression and ejection cycle in as little as 100 to 180 seconds, depending on bale size and machine power.

Energy Efficiency: Advanced hydraulic systems optimize power use, reducing energy consumption while maintaining high output.

Tip: Regularly check and maintain hydraulic fluid levels and seals to ensure consistent pressure and prevent costly downtime in your baling operations.

Key Features of Hydraulic Scrap Metal Steel Copper Baling Press Bale

High Hydraulic Pressure for Maximum Compaction

Hydraulic scrap metal baling presses deliver powerful compression using high hydraulic pressure. These machines generate forces ranging from 125 to 400 tons or more, enough to compact heavy metals like steel, copper, and aluminum into dense bales. The hydraulic cylinders apply pressure from multiple directions—top, sides, and sometimes door cover—to ensure uniform compaction. This high pressure reduces scrap volume by up to 90%, making storage and transportation much more efficient.

The multi-cylinder design allows the baler to press scrap evenly, preventing loose spots inside the bale. This results in stronger, more stable bales that stack easily and resist deformation during handling. The consistent pressure also improves the quality of bales, which is critical for downstream processes like melting or recycling.

Versatility in Handling Different Materials

One of the standout features of hydraulic baling presses is their versatility. These machines handle a wide range of scrap materials, including:

Ferrous metals like steel and iron

Non-ferrous metals such as copper, aluminum, and brass

Plastic waste and packaging materials

Cardboard and paper products

This flexibility makes the baler valuable across industries—scrap yards, metalworking plants, automobile recycling, and packaging companies all benefit. The machine’s adjustable bale sizes and weights accommodate different material densities and processing needs. For example, lightweight aluminum cans can be baled into smaller, lighter blocks, while heavy steel scrap forms larger, denser bales.

Versatility also extends to bale ejection methods. Operators can select side push, front push, or bale flipping systems based on scrap type and workflow, improving operational efficiency.

Energy-Efficient Design

Modern hydraulic scrap metal balers prioritize energy efficiency to reduce operating costs and environmental impact. Advanced hydraulic systems optimize pump and valve operation to use only the power needed for each compression cycle. This reduces electricity consumption without sacrificing bale density or cycle speed.

Some models feature programmable logic controllers (PLCs) that automate pressure and timing, further enhancing energy savings by preventing over-pressurization or unnecessary cycles. Fast cycle times (as low as 100 seconds per bale) also contribute to energy efficiency by maximizing throughput and minimizing idle time.

Additionally, many balers use hydraulic fluid cooling and filtration systems to maintain optimal performance and extend component life. This reduces maintenance needs and downtime, adding to overall efficiency.

Applications of Hydraulic Scrap Metal Baling Press

Usage in Scrap Yards and Recycling Centers

Hydraulic scrap metal baling presses are essential tools in scrap yards and recycling centers. They compress loose scrap metal into dense, uniform bales that are easier to handle, store, and transport. This compaction reduces the volume of scrap by up to 90%, freeing valuable space and lowering storage costs. Recycling centers benefit from faster processing times and improved material flow, as baled scrap is simpler to sort and ship to smelters or manufacturing plants. The baler’s versatility allows it to handle various metals such as steel, copper, and aluminum, making it a one-stop solution for diverse scrap streams.

Automobile and Metalworking Industries

In the automobile industry, hydraulic baling presses help manage scrap from dismantled vehicles, including steel body parts, engine components, and aluminum wheels. These presses compact bulky, irregular scrap into manageable bales, facilitating easier transport and recycling. Metalworking industries use balers to handle leftover cuttings, shavings, and rejected parts. By baling these materials, factories reduce waste volume, improve workplace safety, and optimize recycling processes. The high compaction force ensures even heavy metals are densely packed, maximizing value recovery and minimizing transportation costs.

Plastic and Packaging Industries

Beyond metals, hydraulic baling presses serve the plastic and packaging sectors. These machines compress plastic bottles, films, and packaging waste into tight bales, simplifying storage and shipment. This application supports circular economy goals by enabling efficient recycling of plastics and reducing landfill waste. Packaging companies use balers to manage cardboard, paper, and other fibrous materials, enhancing waste handling efficiency. The adjustable bale sizes accommodate different material densities, ensuring optimal compaction and transport efficiency.

Materials Used in Hydraulic Scrap Metal Baling Press

Structural Frame: Heavy-Gauge Steel

The frame of a hydraulic scrap metal baling press is its backbone. It must withstand immense forces during compression without bending or cracking. Heavy-gauge structural steel, usually high-strength carbon steel, is the preferred material. Thick steel plates are welded together to form a rigid, durable frame. This design ensures the press remains stable under high pressure, providing safety and longevity.

The frame supports all moving parts and absorbs the stress from hydraulic cylinders applying forces up to 400 tons or more. Using lower-grade steel or thinner plates risks frame flexing, which can cause misalignment, reduce bale quality, and lead to costly repairs. The robust steel frame also helps the machine maintain consistent bale sizes and shapes over years of operation.

Hydraulic System Components

The hydraulic system converts fluid pressure into mechanical force. Its key parts include cylinders, pistons, pumps, valves, and fluid reservoirs. The cylinders are typically made from honed steel tubing, which offers a smooth internal surface for piston seals. This precision machining prevents leaks and ensures smooth piston movement.

Piston rods are made from hardened, chrome-plated steel. Hardening adds strength, while chrome plating protects against corrosion and reduces friction. These properties extend the cylinder’s lifespan and maintain consistent pressure output.

Hydraulic pumps and valves are made from high-quality metals and alloys designed to handle high pressures and repeated cycles. These components must resist wear and maintain precise control over fluid flow to ensure efficient compression.

Seals and Fluid Management

Seals are critical to prevent hydraulic fluid leaks under extreme pressure. They are made from durable elastomers such as polyurethane or advanced polymers. These materials resist wear, temperature changes, and chemical degradation. High-performance seals keep the system airtight, maintaining pressure and preventing contamination.

Hydraulic fluid itself requires careful management. It must be clean, properly filtered, and cooled to maintain system efficiency and protect components. Many presses include filtration and cooling systems to extend fluid life and reduce maintenance needs.

Benefits of Using Hydraulic Scrap Metal Baling Press

Cost Reduction in Storage and Transportation

Hydraulic scrap metal baling presses significantly cut costs by shrinking scrap volume up to 90%. This compaction means fewer bales take up less warehouse space, reducing storage expenses. Smaller bale sizes also lower transportation costs since more material fits in trucks or containers. Dense, uniform bales stack more efficiently, maximizing shipping loads and minimizing trips. This efficiency helps companies save on fuel, labor, and logistics fees. Additionally, compact bales reduce handling time, lowering operational costs across the supply chain.

Environmental Sustainability

Using hydraulic balers supports environmental goals by promoting recycling and waste reduction. Compact bales reduce landfill waste by converting scrap into reusable materials. This process conserves natural resources by encouraging metal and plastic reuse rather than mining or producing virgin materials. Efficient baling also cuts emissions linked to transport by reducing the number of trips needed. Energy-efficient hydraulic systems further lower the carbon footprint of baling operations. Overall, these presses help industries align with sustainability standards and circular economy principles, contributing to greener manufacturing and waste management.

Improved Workplace Efficiency

Hydraulic balers streamline scrap handling, boosting workplace productivity and safety. Automated or semi-automated controls reduce manual labor, lowering injury risks. Fast cycle times mean operators can process more scrap in less time, improving throughput. Uniform bales simplify stacking, storage, and loading, reducing clutter and hazards. The machine’s versatility allows quick switching between materials, minimizing downtime. By keeping scrap contained and organized, balers help maintain cleaner, safer work environments. Maintenance features like hydraulic fluid monitoring and seal durability reduce unexpected breakdowns, ensuring smooth, continuous operation.

Choosing the Right Hydraulic Scrap Metal Baling Press for Your Needs

Manual vs. Automatic Models

When selecting a hydraulic scrap metal baling press, deciding between manual and automatic models is crucial. Manual balers require operators to control the compression cycle, often using hand or foot controls. They are usually simpler, less expensive, and suitable for small-scale operations or low-volume scrap processing. However, manual operation can be labor-intensive and slower.

Automatic balers use programmable logic controllers (PLCs) to automate the entire baling process, including loading, compression, holding, and ejection. This automation reduces labor costs, increases throughput, and ensures consistent bale quality. Automatic models excel in high-volume recycling centers or industrial plants where efficiency and speed matter. Semi-automatic models offer a middle ground, automating some functions while keeping others manual.

Factors to Consider: Capacity and Lifespan

Capacity is a key factor when choosing a baling press. It refers to the maximum bale size, weight, and compression force the machine can handle. Balers range from smaller units producing 30–50 kg bales to heavy-duty models compressing up to 1,500 kg or more. Consider the types and volumes of scrap you process regularly. For heavy metals like steel or copper, a higher tonnage press (200+ tons) ensures efficient compaction.

Lifespan is another important consideration. Quality balers built with heavy-gauge steel frames and premium hydraulic components can last 10–15 years or more with proper maintenance. Cheaper models may save upfront costs but risk early wear or failure, causing downtime and repair expenses. Look for machines with durable frames, corrosion-resistant cylinders, and high-performance seals to maximize longevity.

Custom Solutions for Specific Applications

Some operations require customized baling presses tailored to unique scrap types or workflow needs. Customization options include:

Bale size and shape: Adjust dimensions to fit furnace inputs or transport constraints.

Ejection methods: Side push, front push, or bale flipping mechanisms to match material handling setups.

Control systems: Customized PLC programming for integration with existing automation.

Power sources: Electric, diesel, or hybrid options for remote locations.

Additional features: Liquid removal systems for wet scrap, noise reduction, or safety enhancements.

Consulting with manufacturers or suppliers about your specific requirements helps ensure the baler matches your operational demands and maximizes ROI.

Conclusion

Hydraulic scrap metal baling presses play a crucial role in global recycling efforts by efficiently compacting metals like steel and copper. Technological advancements have enhanced these machines' efficiency, making them indispensable for recycling centers and industries. As we focus on sustainability and efficiency, these presses are vital in reducing waste and optimizing resource use. JSHH offers state-of-the-art hydraulic balers that deliver superior performance and value, supporting businesses in achieving their sustainability goals.

FAQ

Q: How does a Hydraulic Scrap Metal Steel Copper Baling Press Bale work?

A: It works by using hydraulic cylinders to apply pressure from multiple angles, compressing scrap metal into uniform, dense bales. This process reduces scrap volume by up to 90%.

Q: Why should I use a Hydraulic Scrap Metal Steel Copper Baling Press Bale?

A: Using this press reduces storage and transportation costs, supports environmental sustainability, and improves workplace efficiency by streamlining scrap handling processes.

Q: What are the benefits of a Hydraulic Scrap Metal Steel Copper Baling Press Bale?

A: Benefits include high compaction force, versatility in handling different materials, energy-efficient design, and improved productivity in scrap yards and recycling centers.

Q: How does a Hydraulic Scrap Metal Steel Copper Baling Press Bale compare to manual models?

A: Automatic models offer increased throughput and consistent bale quality, reducing labor costs compared to manual models, which require more operator control and are suited for smaller operations.