Are you looking for the best horizontal baler for your facility in 2025? You need a machine that matches your waste amount. It should handle the materials you use. It must also fit in your space. The market for horizontal balers is getting bigger. More people are buying them because they help work faster. They also help with e-commerce packaging waste.

Did you know?

Market Size (2024) | Projected Market Size (2031) | CAGR (2024-2031) |

USD 657 million | USD 920 million | 5.6% |

Picking a baler that fits your needs helps your daily work. It also helps your business grow in the future. The Huanhong Horizontal Baler gives strong performance and is very reliable for big recycling jobs.

Key Takeaways

Pick a horizontal baler that fits your waste type and amount. This helps your work go faster and smoother. Measure your space to make sure the baler will fit. You need room to load and fix the baler easily. Think about automation like smart controls and bale tying. These can save work and help you do more. Check for good safety features and follow safety rules. This keeps your team safe and follows the law. Think about long-term costs like energy, fixing, and help from the supplier. This will help your baler last a long time.

Key Considerations When Choosing a Recycling Baler Machine

When you pick a baler, you need to think about a few things. These things help you choose the right recycling baler machine for your needs. They also help your business work better and grow. The Huanhong Horizontal Baler is strong and works well in busy places.

Waste and Material Needs

First, you should know what waste you have. The amount and type of materials you use every day matter. This helps you pick the recycling baler machine that fits your job. Most businesses use horizontal balers for these:

Cardboard like boxes and shipping cartons

Paper such as office paper and magazines

Plastics like bottles and containers

Aluminum cans and other light metals

These are the most common things for recycling baler machine jobs. If you have lots of cardboard, paper, or plastics, you need a baler that can handle them. The Huanhong Horizontal Baler can process many types of recyclables. It is good for places with different waste needs.

Facility Space

The space in your building is important. Horizontal balers are bigger than vertical ones. They need more room to work. You should plan for:

Enough space for the baler and other parts

A strong floor to hold the machine

Easy access for trucks and no things above

Good electrical connections and enough height

Putting your recycling baler machine close to waste spots saves time. It also helps your team work faster. The Huanhong Horizontal Baler is great for busy places. You should check your space to make sure everything fits.

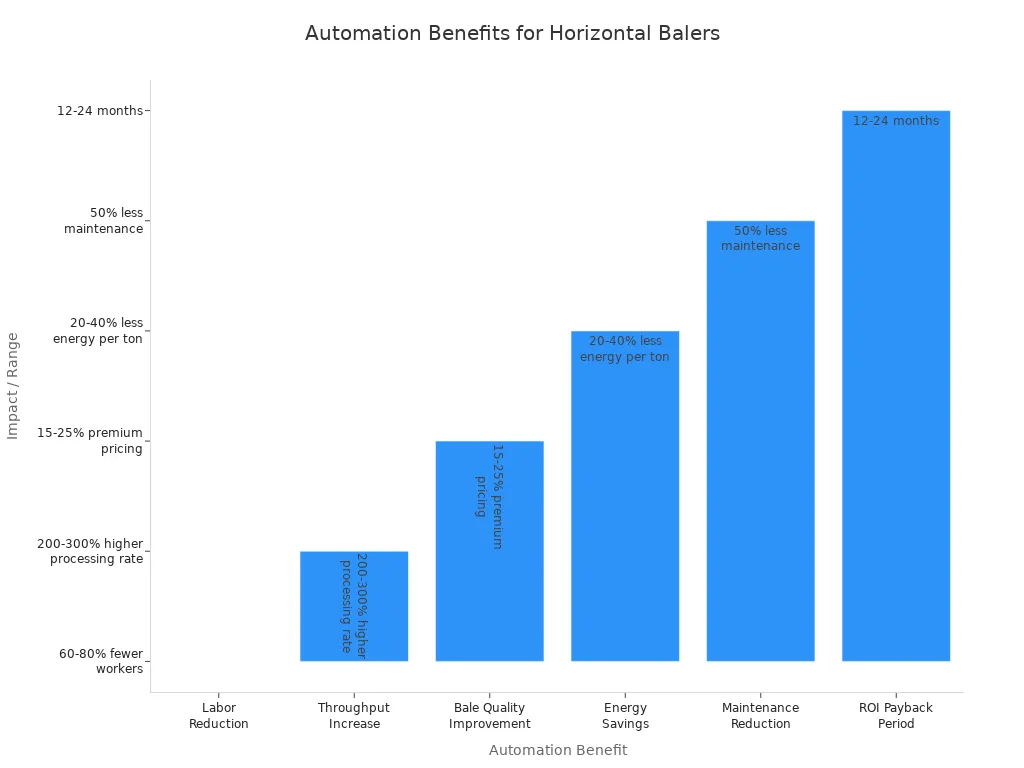

Automation Options

Automation is a big thing to think about when picking a recycling baler machine. Automated balers help you work faster and need less people. You can pick manual, semi-automatic, or fully automatic models. Some cool features are:

Smart controllers for easy use

Robots to tie bales without hands

Sensors to stop jams and mistakes

Conveyors for nonstop feeding

Tip:

Full automation can cut labor by 90%. It can also make work go 200-300% faster. Smart sensors and special features help stop problems and save money.

The Huanhong Horizontal Baler has smart automation. It helps you get more done and spend less.

Bale Size and Output

You should think about bale size and how much the recycling baler machine can make. Bigger and tighter bales save space and cost less to move. The kind and amount of waste you have will change the bale size you need. The Huanhong Horizontal Baler makes strong, even bales. This helps you manage waste and move it easily.

Safety Features

Safety is very important when using recycling baler machines. New machines must follow strict rules. Some safety features are:

Guards on moving parts and doors

Closed panels for wires and quick fixes

Checks on hydraulic parts and the frame

Training for workers and clear guides

Lockout steps for fixing the machine

Warning signs and safety gear

Your team should always follow safety rules. The Huanhong Horizontal Baler has good safety tools to keep people safe and follow the law.

Cost of Ownership

Knowing the total cost is one of the key things when picking a recycling baler machine. You should look at more than just the price. Think about:

Cost Component | Typical Range / Estimate |

Purchase Price | $25,000 - $48,000 (standard industrial) |

Installation Cost | $1,500 - $15,000 |

Annual Maintenance | 7% - 12% of machine purchase price |

Energy Costs (280HP) | About $3,100 each year |

Energy Savings | Up to 19% less with good valves |

Good recycling baler machines like the Huanhong Horizontal Baler help you save energy and money. They also break down less and last longer.

Supplier Support

Good supplier support keeps your recycling baler machine working well for years. You should look for:

Warranty that covers many things

Fast help and easy-to-get parts

Help with setup and training

Tech support and online help

Emergency visits and updates

The Huanhong team gives full help from start to finish. This lets you focus on your main work. Good supplier support is needed for long-term success.

Note:

If you think about these key things when picking a recycling baler machine, you will make a smart choice. This helps your waste plans and helps your business grow. Using a recycling baler machine makes work easier, costs less, and keeps your place clean.

What Is a Horizontal Baler?

Horizontal vs. Vertical Balers

It is important to know about different recycling baler machines before you buy one. A horizontal baler is special because it can handle lots of waste every day. You put materials inside, and the machine squeezes them from the side. This design lets you keep adding waste without stopping. You get tight bales that are easy to move and store.

Vertical balers work in another way. They press waste from the top down. These machines are smaller and fit in small spaces. You use vertical balers for less waste, like cardboard or plastic bottles. They make neat bales you can stack, but they are not as fast or strong as a horizontal baler.

Tip:

Pick a horizontal baler if your business has lots of waste and needs fast work. You will notice how a recycling baler machine helps you do more with less effort.

Key differences between horizontal and vertical balers:

Horizontal balers are bigger and made for lots of recycling.

They let you keep feeding waste and make tight bales.

Vertical balers are small and good for less waste.

Vertical balers need less floor space but need more height.

Typical Applications

You see horizontal balers in places with lots of recyclables. These machines work best in recycling centers, warehouses, and big packaging plants. You can use a horizontal baler for cardboard, paper, plastics, textiles, and scrap metal. The machine makes big, heavy bales that save space and lower shipping costs.

Huanhong’s horizontal baler is made for busy jobs. It gives steady performance and the same results every time. The machine can run all day, so you can keep working. You also get features like automatic bale tying and built-in conveyors, which help your team work faster.

When you pick the right baler, you recycle better and help the planet. You will see how different recycling baler machines fit different jobs, but a horizontal baler gives you the power and speed for big tasks.

Baler Features to Evaluate

Feed Opening and Compression Force

When picking a horizontal baler, check the feed opening and compression force. These baler features show how much you can put in and how tight your bales will be. A wide feed opening lets you load big boxes and bulky plastics. You can also add mixed recyclables without jams. Most commercial balers have feed openings from 5 to 20 feet long and 3 to 6 feet wide. This size works for both hand feeding and conveyor feeding.

Parameter | Typical Range/Value |

Feed Opening Size | Length: 5 to 20 feet; Width: 3 to 6 feet |

Bale Size | 750 x 750 mm to 1100 x 1250 mm |

Compression Force | 1,000 to 10,000 lbs (small); 60-200 tons (industrial) |

A strong compression force, up to 200 tons in big models, makes dense and even bales. The Huanhong Horizontal Baler uses a powerful system to handle lots of material. It makes bales that are easy to stack and move. This helps your team work better and lowers shipping costs.

Build Quality and Durability

You want a baler that works for many years, even with heavy use. Build quality is one of the most important baler features. Look for a strong steel frame, plates that lock together, and bolt-in liners. These parts help the machine last longer and run smoothly. Good hydraulic systems and tying parts keep your bales tight and stop breakdowns.

Factor | Impact on Lifespan |

Quality of Components | High-quality parts extend machine life |

Maintenance Practices | Regular servicing reduces wear and tear |

Operational Conditions | Harsh environments shorten lifespan |

Material Types Processed | Tougher materials may lead to quicker wear |

The Huanhong Horizontal Baler uses tough steel and smart hydraulics. This design gives steady performance and a long life, even in hard places.

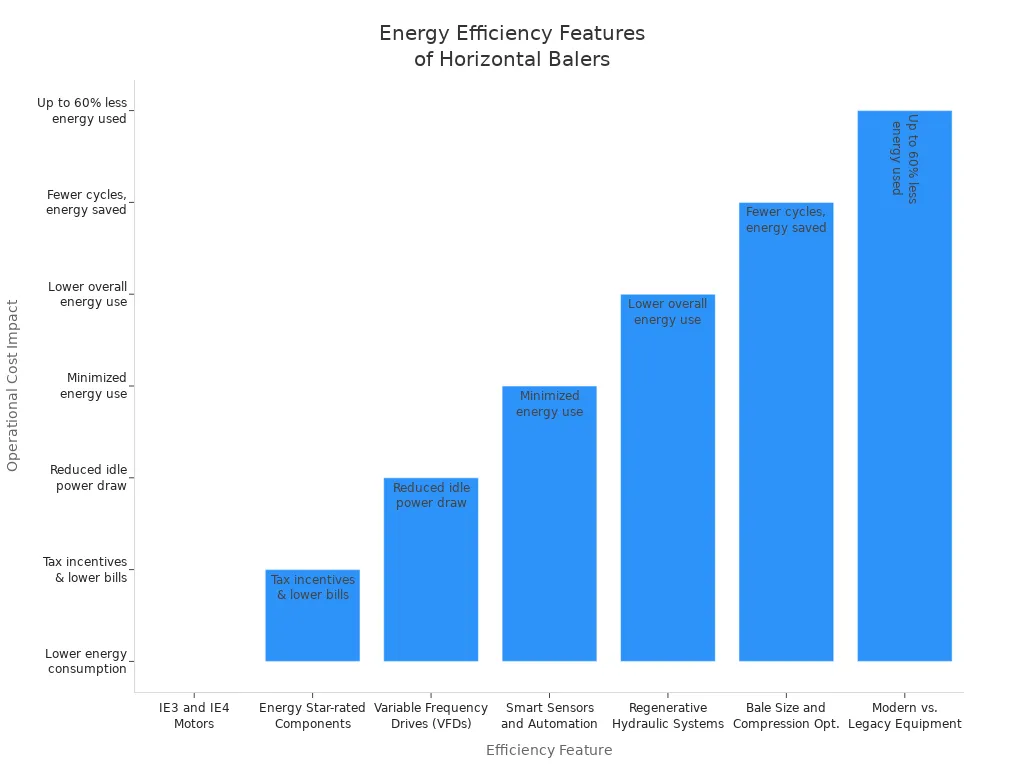

Energy Efficiency

Energy efficiency is important when you look at baler features. New balers use motors that save energy, smart sensors, and drives that change speed. These tools can cut energy use by up to 60% compared to old machines. You save money on bills and help the planet.

Energy Efficiency Feature | Description | Impact on Costs |

IE3/IE4 Motors | High-efficiency electric motors | Lower electricity use, possible rebates |

Variable Frequency Drives | Adjust motor speed to load | Reduce power draw, extend motor life |

Smart Sensors & Automation | Auto-shutoff, real-time monitoring | Minimize energy waste, reduce labor hours |

Regenerative Hydraulics | Reuse energy during baling | Lower energy use, less wear on components |

The Huanhong Horizontal Baler has these smart energy-saving features. You pay less and help your company go green.

Cardboard Baler and Material Compatibility

Cardboard, Plastics, and More

When picking a cardboard baler, think about what materials you have. Cardboard, plastics, and textiles are all different. Cardboard is light and soft, so it is easy to press. Plastics like PET bottles or HDPE containers are harder and need more force. Metals, such as aluminum cans, need even more pressure and sometimes special cutting tools. Your cardboard baler should work with these materials for good waste management.

A horizontal baler can handle many types of recyclables. You can use it for:

Cardboard boxes and corrugated sheets

Mixed paper and magazines

Plastics, including PET and HDPE

Textiles and light metals

This means you can bale big, heavy, or mixed loads with one machine. The Huanhong Horizontal Baler makes tight, even bales that save space and cut down on shipping costs. Automation helps you bale more things faster, so your waste system works better.

Tip:

Always sort plastics and cardboard before using your cardboard baler. This stops jams and keeps your work going well.

Adjusting for Material Types

You need to change your cardboard baler settings for each material. For plastics, use more force to press them tight. For cardboard, use normal pressure to make strong bales. If you bale textiles or mixed stuff, check the feed and change the cycle time for best results.

Follow these steps to get the most from your cardboard baler:

Pick the right force for each material.

Change the feed opening for big or odd items.

Use automatic tying to keep working without stopping.

Do regular checks to stop clogs and help your machine last.

The Huanhong Horizontal Baler makes these changes simple. Its strong hydraulics and smart controls let you switch materials fast. You get steady results for all your waste jobs, whether you bale cardboard, plastics, or textiles.

Space and Installation

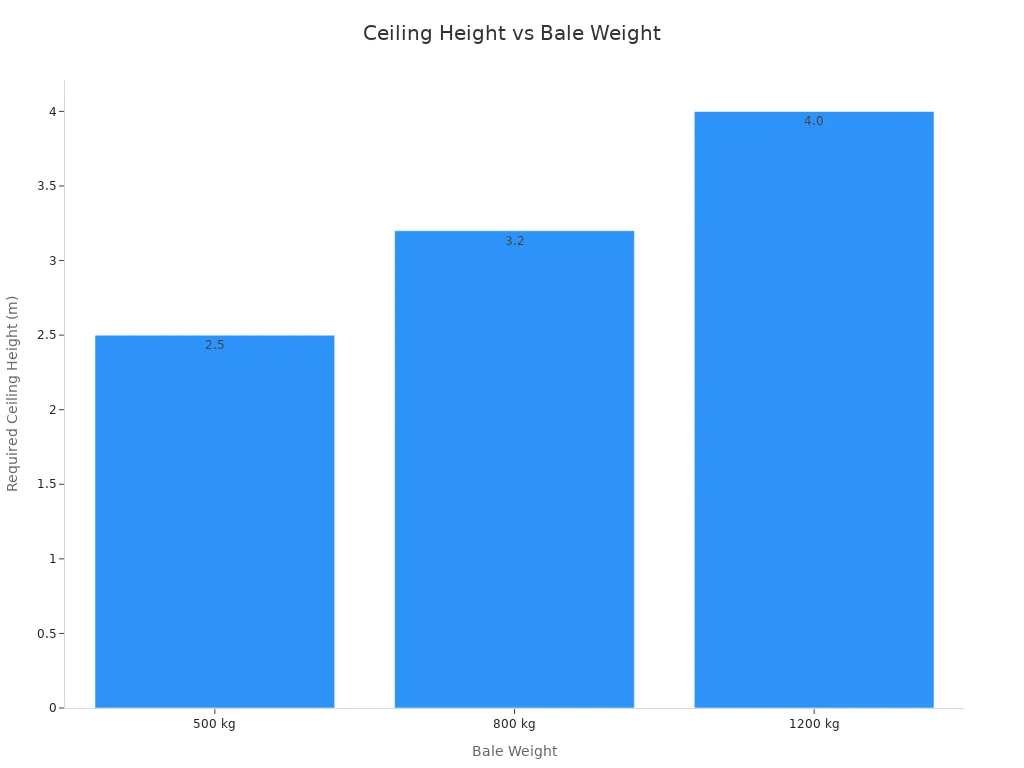

Footprint and Layout

When you get a horizontal baler, you need to check your space. Horizontal balers take up more room than vertical ones. You should have at least 50 square meters of floor space. This gives enough room to use the machine safely and walk around it. Put your baler close to where you keep waste. This makes work faster and easier.

Ceiling height is also important. Many horizontal balers need a ceiling at least 3 meters high. The height you need depends on the bale size and chamber. For example, if your baler makes 800 kg bales, you may need 3.2 meters. If you do not measure right, you might have to change your building. One company had to fix its warehouse because the baler did not fit through the door. Always check your layout and ceiling height before buying.

Criteria | Vertical Baler | Horizontal Baler |

Minimum Floor Space | Less than 20 m² | More than 50 m² |

Suitable For | Low volume, small area | High volume, ample space |

Installation Notes | Simple, small footprint | Needs more space, planning |

Tip:

Measure all doors, walkways, and ceiling heights before you install. This helps you stop delays and extra costs.

Loading and Access

You need to think about space and how you will load the baler. The baler should not block paths or work areas. Make sure there is room for forklifts, carts, or conveyors to move things in and out. The spot you pick should let you use and fix the baler safely.

You also need to plan for power and hydraulic lines. The floor must be strong enough, and you need enough power for the baler. Good planning helps you avoid slowdowns and keeps your recycling moving well.

If you plan well, your Huanhong Horizontal Baler will fit and work great for your recycling jobs.

Automation and Operation

Manual vs. Automatic

When you pick a horizontal baler, you must choose how much automation you want. Manual balers need you to put in materials by hand. You also start each cycle and tie bales yourself. You must remove bales when they are done. This takes more time and needs more workers. Semi-automatic balers do some steps for you. But you still have to start cycles and take out bales. You may need to tie bales by hand, which can slow things down.

Fully automatic horizontal balers, like the Huanhong Horizontal Baler, make waste jobs easier. These machines use sensors and smart controls. They feed materials, start cycles, tie bales, and push them out without you doing it all. You get more bales made and better bale quality. You also spend less money on workers. Automatic tying is faster and safer than tying by hand. Workers stay away from moving parts, so there is less chance of getting hurt.

Tip:

If your facility has lots of recyclables, a fully automatic baler helps you process more with fewer workers and less waiting.

Baler Type | Operator Tasks Required | Throughput | Safety Level |

Manual | Feed, start, tie, remove bales | Low | Basic |

Semi-Automatic | Some feeding, cycle start, removal | Medium | Moderate |

Fully Automatic | Supervise, monitor | High | Advanced |

Conveyor Integration

Adding a conveyor makes your baler system work better. When you use a conveyor with your horizontal baler, it feeds waste in automatically. The baler chamber stays full and ready to press. This means less work for people and faster baling. You do not get slowdowns, and your recycling line keeps moving.

Conveyors load waste nonstop and make more bales.

Automated feeding lowers worker costs and keeps people less tired.

Conveyor systems fit into your current setup, so installing is easy.

You can handle more waste without slowing down.

The Huanhong Horizontal Baler works with conveyors, so you can make your recycling jobs better. You get a smooth system that helps your team do other work. With automation and conveyor support, your facility stays fast and ready to grow.

Safety and Compliance

Operator Safety

When you use a recycling baler machine, safety is very important. New machines have many features to keep you safe. Here are some key safety parts you will find on a good recycling baler machine:

Emergency stop buttons help you stop the machine quickly if there is a problem.

Safety interlocks make sure the recycling baler machine does not run when doors or gates are open.

Safety guards cover moving parts like the ram, belts, and pulleys so you do not get hurt.

Protective covers keep you safe from leaks or bursts in the hydraulics.

Sensors can find jams or too much material and will stop the recycling baler machine to avoid damage.

Automation, like automatic bale tying, means you do not have to touch moving parts as much.

You should always load the recycling baler machine safely. Keep your hands away and use tools to push materials inside. Stand back when bales come out and use the right lifting tools. It is also very important to train everyone. Make sure all workers know how to use the controls and follow safety steps. Check the recycling baler machine often to find problems early, like broken guards or leaks.

Tip:

Always look at warning labels and follow lockout/tagout steps before you clean or fix your recycling baler machine.

Regulatory Standards

You need to make sure your recycling baler machine follows all safety rules. In the United States, OSHA and ANSI make the main rules for recycling equipment. The ANSI Z245.5-2023 rule says how to install, use, and fix the machine safely. It says you must have emergency controls, interlocks, guards, and clear safety signs. OSHA rules say you must use lockout/tagout steps to control dangerous energy when fixing the machine.

Manufacturers build recycling baler machines to meet or go beyond these rules. You will see things like UL-approved controls, NEMA 12 enclosures, and safety interlocks that stop the machine if a door opens. These rules help stop accidents and keep your team safe every day.

If your recycling baler machine meets these rules, it is safe and reliable. You can trust your equipment to help keep your workplace safe and follow the law.

Cost and Maintenance

Purchase and Operating Costs

When you buy a horizontal baler, you should think about more than the price tag. The total cost means you pay for the machine, energy, workers, and fixing it over time. In 2025, horizontal balers can cost from $20,000 to $200,000. The price depends on how big it is, what features it has, and if it has automation. Most companies see that a good baler, like the Huanhong Horizontal Baler, pays for itself in two or three years. Automation helps you use fewer workers and makes bales tighter, so shipping costs go down.

Baler Type | Price Range | ROI Period | Key Benefits |

Horizontal Baler | $50,000 – $200,000 | 2-3 years | High capacity, automation, efficiency |

You also need to think about how much it costs to run the baler. The Huanhong Horizontal Baler uses motors and smart controls that save electricity. Automation means you do not need as many workers, so you spend less money on staff. These savings grow over time and make your baler a good choice.

Tip:

Picking a strong and efficient baler helps you spend less money in the long run and keeps your recycling working well.

Maintenance Needs

Doing regular checks keeps your baler working well and stops expensive breakdowns. You should have a plan to look at and fix important parts often. Each month, check the conveyor belt, test the hydraulic oil, and set up the wire dispenser. These jobs help you stop jams and tying mistakes that can slow down work.

Key maintenance tasks:

Look at and oil moving parts like hydraulic cylinders, belts, and bearings.

Clean the machine and hydraulic parts to stop leaks or clogs.

Test the hydraulic oil and change filters so the baler does not get too hot.

Check the conveyor belt and wire dispenser settings.

Make sure all safety parts work right.

Fixing small problems early helps you avoid bigger trouble later. The Huanhong Horizontal Baler is made with strong steel and smart parts, so fixing it is easy and quick. If you take care of your baler, it lasts longer and keeps your recycling going.

Doing regular maintenance means your baler breaks down less and works better for your business.

Planning for Growth

Scalability

You want your recycling system to grow with your business. Horizontal balers let you handle more waste as you get bigger. You do not need to buy new equipment right away. These machines work with many materials like paper, plastic, metal, and textiles. You can change what you recycle as your needs change. Modern horizontal balers can process lots of waste fast. This helps you keep up when your facility gets larger.

Key ways horizontal balers help you grow:

Handle many kinds of recyclables as your needs change

Pick manual, semi-automatic, or fully automatic models for your growth

Add smart technology for live monitoring and fixing problems early

Change baler types and features for your waste streams

Make tight bales to save space and lower shipping costs

Cities and industries are getting bigger. New rules and green goals mean better waste management is needed. Horizontal balers help you meet these needs. They make your work faster and easier to change.

Future-Proofing

Planning ahead means picking a baler that stays useful as recycling changes. Look for good supplier support, easy upgrades, and a strong warranty. Regular checks and service plans keep your baler working well and lasting longer. Training at your site helps your team use the machine safely and well.

Service Option | Benefit |

Regular Maintenance | Stops breakdowns, saves money |

On-Site Training | Makes work safer and better |

24/7 Support | Fast help when you need it |

Spare Parts Access | Less waiting for repairs |

Custom Upgrades | Fits new recycling needs |

Warranty Coverage | Keeps your investment safe |

You can pick balers with automation, IoT, and data tools. These features show you what is happening right now and help you plan for growth. If you buy a horizontal baler with good support and upgrade choices, your business will be ready for the future.

Picking the best recycling baler machine in 2025 means you need to think about how much waste you have, how much space you need, if you want automation, and how safe the machine is. Make a checklist so you can compare each recycling baler machine easily. When you talk to suppliers, ask them to show you how the recycling baler machine works. This lets you see if it fits your needs and helps you choose. Follow these steps to help you pick the right recycling baler machine:

Look at your waste amount and space.

Check for automation and safety features.

Compare how easy it is to fix and get help.

Ask for demos to see how the machine works.

Think about long-term costs and if the supplier is reliable.

The Huanhong Horizontal Baler is strong and works well for big recycling jobs. If you want to feel sure about your choice, reach out to our team for a price or to learn more about the best recycling baler machine for your business.

FAQ

How do you know if a horizontal baler fits your facility?

First, measure your floor space and ceiling height. Next, look at how much waste you have. Think about what kinds of materials you need to bale. The Huanhong Horizontal Baler is best for big spaces and lots of recycling. If you are not sure, you can ask our team to check your site.

What materials can you process with the Huanhong Horizontal Baler?

You can use this machine for cardboard, plastics, paper, textiles, and light metals. It can handle mixed recyclables without problems. Every time you use it, you get tight and even bales.

How often should you maintain your horizontal baler?

Check and service your baler once a month. Clean the moving parts and look at the hydraulic oil. Test all safety features to make sure they work. Doing this helps your Huanhong Horizontal Baler last longer and run well.

Can you upgrade your baler as your business grows?

Yes, you can add things like automation, conveyors, or smart controls. The Huanhong Horizontal Baler is made so you can upgrade it later. This means you are ready if you get more waste or new recycling jobs.

Is training provided for new operators?

Yes, you get training at your site when you set up your Huanhong Horizontal Baler. Your team learns how to use it safely and how to fix small problems. This training helps you get the most from your machine.