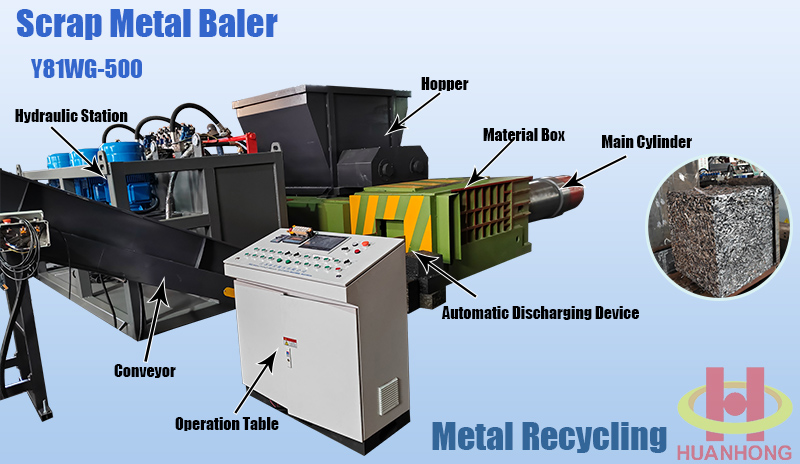

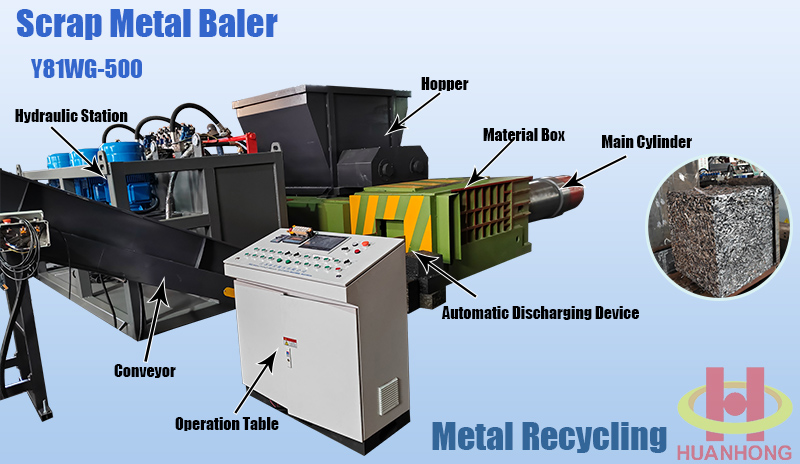

Introduction of scrap metal baler

This is a 500-ton high-density hydraulic metal baler, which is specially designed and manufactured for customers. It is mainly used to process the scrap copper generated in the production and manufacturing of customers. This hydraulic metal baler adopts the feeding method of automatic feeding of storage bin and hopper. Workers only need to add scrap copper into the storage bin, and the scrap copper is put into the hopper through the conveyor belt. Under the operation of the auger, the scrap copper automatically falls into the bin of the metal baler. The metal baler starts to work and compresses the loose scrap copper into a dense rectangular block through external force. The discharging method of this hydraulic metal baler is side-push discharging. The scrap copper bales are pushed out of the bin and fall on the conveyor belt and are automatically transported to the bale collection box. In the whole process of scrap metal material processing, fewer workers are needed. It only needs to be operated through the buttons on the operating table, or it can be controlled by the infrared remote control. The operation is very simple and safe.

Parameter of the scrap metal baler

Model | Nominal Force | Material Box Size | Bale Sectional Size

| Motor Power |

Y81WG-500 | 5000 KN | 1700*1400*550 mm | 300*300 mm | 135 KW |

The above parameters are for reference only.

Application of scrap metal baler

High-density hydraulic metal balers can handle various scrap metals, such as scrap steel, scrap iron, scrap aluminum, scrap copper, scrap titanium and other metal materials. These scrap metals can be processed in various shapes, including metal sheets, metal blocks, metal chips, metal shavings and other scrap metal scraps. The emergence of high-density scrap metal balers efficiently handles these loose scrap metal materials, compressing them into regular high-density rectangular blocks, which are easy to store and transport, and effectively realize the recycling of resources.

Baler Recommendation

Our company specializes in the production of hydraulic metal balers for various scrap metal processing. Based on the different ways of discharging materials, our balers are divided into manual grabbing type, push-out type and flip-out type.