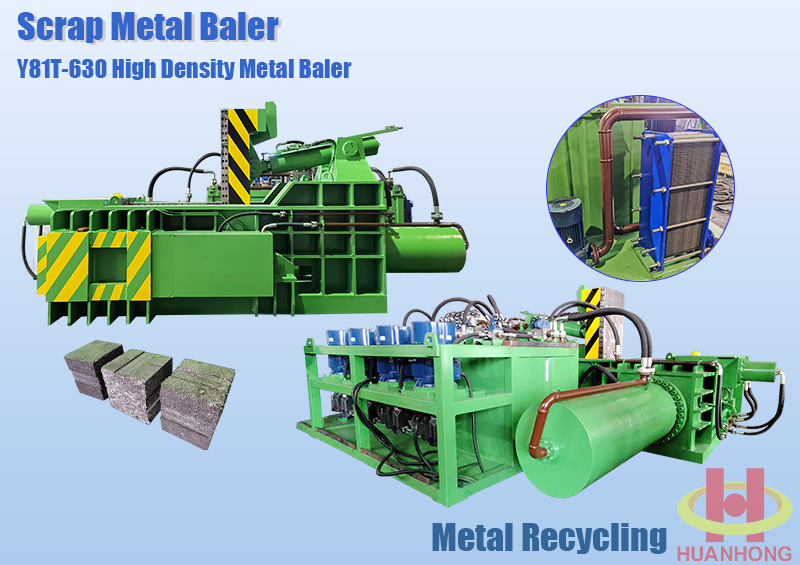

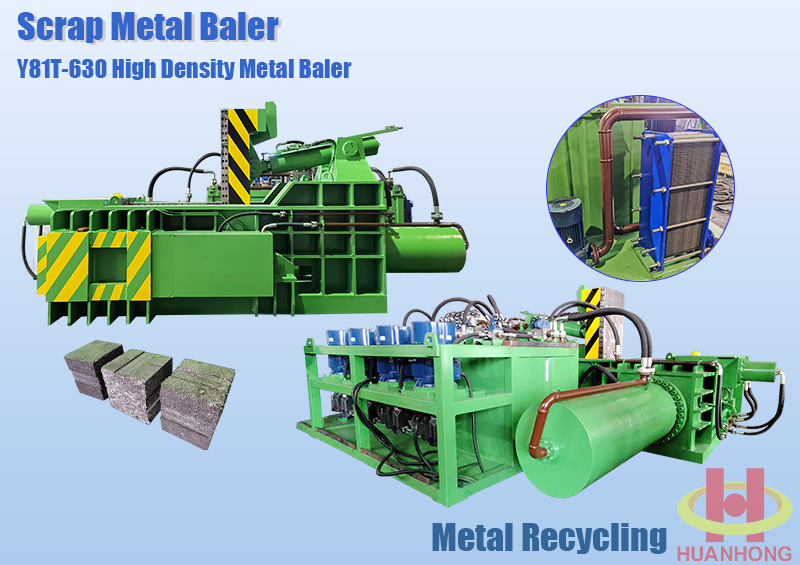

Introduction of the high density metal baler

Hydraulic metal balers play an important role in the scrap metal recycling industry, metal processing industry, steel smelting industry, etc. The main purpose of the hydraulic metal baler is to compress scrap metals of various shapes into regular high-density rectangular blocks through external force. The processed scrap metal blocks are more convenient for storage, transportation and later recycling and reprocessing. This Y81 series high-density hydraulic metal baler model is Y81T-630. Its main cylinder pressure is 6300KN, and it has a side-push discharging method. The cross-sectional size of the scrap metal block is 300*300mm.

Technical specification of the high density metal baler

Technical specification of Y81T630 metal baler |

Model | Y81T-630 |

Nominal pressure(kn) | 6300 |

Bin size(L*W*H)(mm) | 1200*800*800 |

Bale size(W*H)(mm) | 300*300 |

Power(kw) | 148 |

The above parameters are for reference only. The balers can be customized.

Features of the high density metal baler

1. Efficient compression capability: The high-density hydraulic metal baler is hydraulically driven and can generate huge pressure, easily compressing scrap metals such as scrap steel, scrap aluminum, scrap copper, etc. into high-density bales.

2. Automatic discharge function: It can automatically remove the compressed metal blocks from the material box, greatly saving labor costs.

3. Various ways of discharging: There are various ways of discharging, including turning the bag, side push, front push or manual material collection, which can be selected according to the actual site and needs.

4. No anchor screws are required: No anchor screws are required for installation, which is convenient for moving and rearranging.

Applications of the high density metal baler

Hydraulic metal balers are indispensable and efficient equipment in the field of metal recycling and processing. They are widely used in multiple industries, helping companies optimize resource utilization, reduce operating costs and improve environmental benefits. In the scrap metal recycling industry, whether it is scrap steel, scrap aluminum or scrap copper, hydraulic metal balers can compress these scrap metals into high-density regular blocks, greatly reducing the volume, facilitating efficient transportation and storage, while providing convenience for subsequent smelting and reprocessing, significantly improving resource recycling utilization. With its efficient, flexible and reliable performance, hydraulic metal balers have become key equipment for the metal recycling and processing industry to improve efficiency, reduce costs and achieve environmental protection goals.

Related Recommendations

This series of hydraulic metal balers can be divided into three categories according to the discharge form, namely push-out type, flip-out type and manual grabbing type. Hydraulic metal balers can be classified according to the hydraulic pressure, ranging from 125 tons to 4000 tons, with more than a dozen levels.